So I got a xr with a RW cut45 a few weeks ago. The thc has never worked always tried to cut at like .25 off material so I just run it off. Hasn’t been to much of an issue but also haven’t had time to mess with it much. Now today did some small brackets outta 12 gauge and with the thc off its trying to pierce at .25 and not piercing at all until moving a 1/4 inch or so. Cut height is .055 and pierce is set to .1 in fusion on my tooling. it’s even doing it on the straight cut in fire control any ideas I called today and left a message but wondering if anybody has had this issue. this is all at 98 ipm 45 amps 180 psi to the machine 58 on the gauge water Seperator and filter.

@Grif Welcome to the forum.

Any more details on how it not working right or the errors it is throwing?

What is the current state of your consumables? Make sure you are not using a drag shield

So you have the XR correct?

This is to short of Pierce needs to be .7 or .8

Should pierce at .150 and cut at .065

I take it 180 = 80?

58 on the gauge while cutting or while holding the button in on the cutter?

Try raising air to 65 while cutting or holding button in on front of cutter

Welcome to the forum.

Just to clarify: “pierce” is your pierce height. Pierce height is recommended to be about 250% of you cut height.

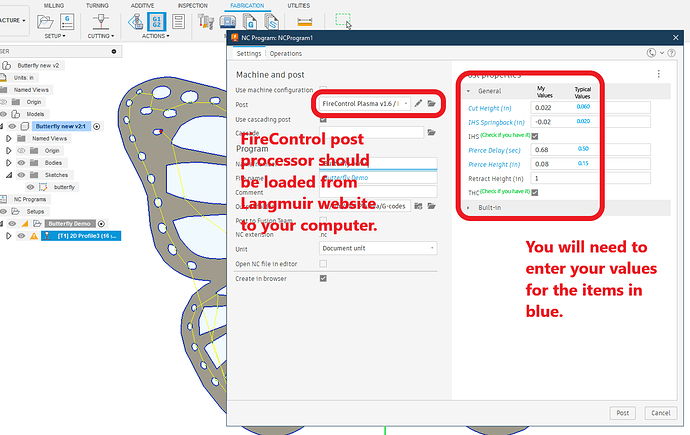

I don’t believe you gave us your “pierce delay”. These are the values that might be helpful for us to know each of them:

No drag tip brand new fine cut consumables. The thc has always tried to cut way too high as it cuts it climbs

Pierce hight is set to .1 pierce delay is .8. 180psi into the machine

Not the appropriate consumables for quarter inch plate.

Maybe you have a bit of a sticky IHS? Do you notice the green IHS light coming on when it is not checking the initial height?

At least for a hypertherm that’s way too high of an inlet pressure. I have everything after my compressor tank set to 120 PSI.

It’s not 1/4 plate it’s 12 ga and it’s something going on that’s what I’m trying. To figure out lol

Sorry I should have known it was height not delay with that being said height should be .150 for a RW45

I set it lower to try to compensate

You need to go higher if you are at .1 you need to raise it to .150

having to low will ruin your consumables

I think he was trying to compensate for the pierce starting early… ie set at .15 but actually initiating at .25

Sounds like a IHS switch issue as Tin suggested.

@Grif is there anything stopping the IHS from touching off on the metal, or something causing the IHS to trip before it touches? Can you get a video focusing on the movement of the Z axis.

I was trying to compensate yes and last night I took at bolt meter and checked it at the control box and as soon as it switches I lose closed loop like I should so I really don’t understand. Nothing in the way it can drop a quarter inch below the slats like it should I really don’t understand

Green light only comes on when checking height like it should but I did notice if I get my finger in there to make it come on it is a bit delayed