Anybody on here have the torch head have a melt down where you had to replace the torch head because of the damage. I can no longer install fresh electrodes and tips and damaged the piston on my innotech IPTM100 machine torch. I didnt get a good answer from everlast tech support other than a possible 1000 different causes. My guess is water intrusion from the table. ( i really dont lnow though) aslo found out even though my torch is fairly new and within the warranty this damage is not covered. Currently researching getting a hypertherm head for my torch leads.

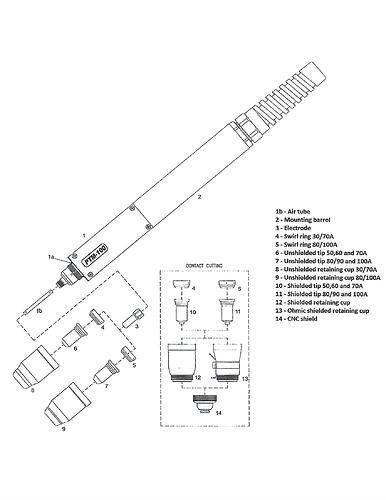

I can say most likely you over extended the Electrode causing this. The electrode is hollow except doe the end were the hafnium is. There is a air tube that the electrode goes over it is there to keep the electrode cool. When the electrode is not changed out in time it will melt the end of the torch head.

I have seen this happen on the 80 amp, 100 amp and 125 amp torch’s as well as others.

I had brand new consumables on the torch just prior to cutting. Program was only 3 minutes of cut time at 45 amps. Just wonder how to try to prevent this in the future. Each new project i put on new consumables. I have to say that the razorweld 45 consumables way out last the innotech machine torch consumables. I am using the 100 amp 1.5 tips too.

So why are you using 100 amp consumables at 45 amps??

And are you sure you are using the right consumable combination?

You should be using 1.0mm/50 amp consumables at 45 amps.

I run an Everlast 62i…post flow and consumable life are key with these torches…how is your post flow air?..I run mine no less that 30 seconds after any cut…and when cutting more that 5 minutes cut time I like to give the torch a good cool down time.

All i have is the 100 amp tips. I bought a 200 piece kit when i bought the machine.My postflow is maxed out at 1 minute. I would imagine that the only drawback to using 100 amp consumables is larger kerf at lower amps than with for instance 1.0 tips. I wouldnt have expected shortened life at lower amps.

I have a PTM60 machine torch. On ome of the electrode changeouts, I didn’t tighten the electrode. The torch cut fine for a minute, then crappy and then no cut. Took off the cap and found the electrode disintegrated and frozen in the torch head.