I have been using this machine for some time now and have figured out most of the little issues but this one has me scratching my head.

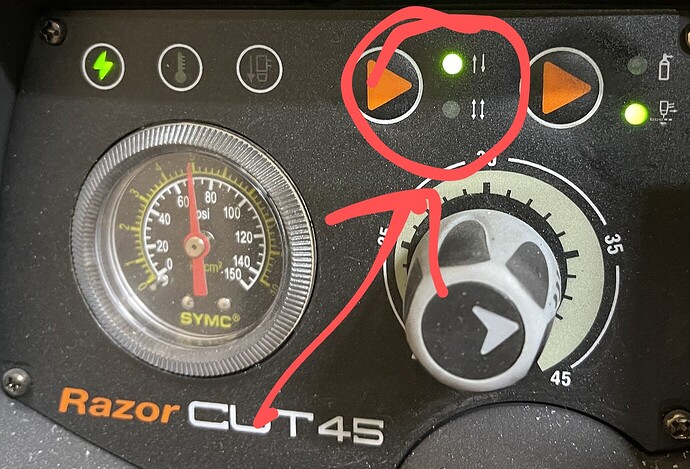

Razorweld 45 cuts fine on the initial cut, moves than wont fire on second cut. If i reset it and wait for the air to stop its flow and restart, it will cut and follow same pattern.

Does not matter what I have set for delay, I’ve increased manually up to 250% and down to 50% with the exact same result. Cut fine then fault out on second cut.

I’ve drained my air tanks, change my desiccants, installed new consumables & swirl ring, cleaned and lubed everything possible and nothing changes.

It could be your air supply. The internal pressure regulator may be malfunctioning, pressure is lower than you might think in your line. Check the pressure at the back of the machine and monitor it during the cuts/attempted cuts. Increase air pressure and see if you have better success.

Ive read through a couple issues like that on here and made sure that was set properly. Still having the same issues.

Thanks, ill try this out.

I have had that happen with my Hypertherm Sync 45. I also manually increased the delay, I even modified the gcode with longer delay and reloaded it, it didn’t work. I restarted the CNC controll box, restarted FireControll reloaded the gcode that I changed the delay to .6 with Sheetcam and it worked perfect.

I’m still learning this stuff so take what I just said with a grain of salt… as they say.

No, it is all helpful information. Hypertherm is notorious for needing more time added to the pierce delay.

Rarely have I got by with 0.5 seconds, usually at 0.6 but not always and now I am resting around 0.72 seconds with my Hypertherm 45XP. It may be too long for some cuts but appears to get all of them. When you are making a quick bracket, the last thing you want to fuss with is the perfect pierce delay.