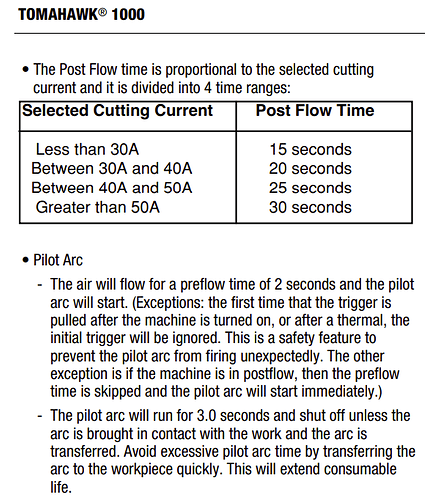

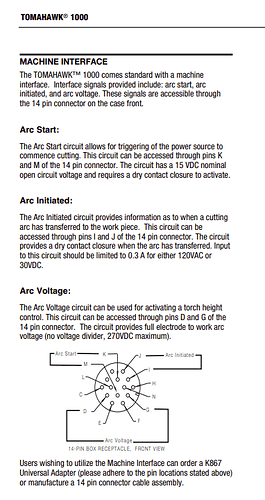

I have a Lincoln Tomahawk 1000 plasma cutter. I have been having a problem cutting from one loop to another. I have found out that with the Tomahawk when it stops cutting it has post cooling air that is hard wired the length of time and is determined by the current setting. In hand held torch usage you can release the trigger to stop cutting and refire the torch but you must hold the trigger in for 2 seconds it then stop the air a refirers the torch, this function is hard wired in the torch. Not sure how to make this work on the CF table when moving to a new cut loop. My understanding of torch delay is this is the delay time once it moves to a new cut loop before it fires the torch. This does not help me because the post air is still blowing and the torch trigger must be engaged for at least 2 seconds for the air to stop and refire the torch on the Tomahawk 1000

I have no answer yet but I thought I’d post the manual and a few clips to get others started on figuring it out.

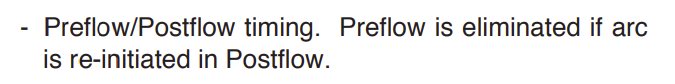

The pre-flow setting is only for the first trigger after that when in post-flow it will re-trigger with out the 2 second pre-flow.

The way I read that, the first trigger signal is ignored. The second trigger signal initiates a 2 second pre flow before the pilot arc is fired. Any subsequent trigger signals skip the 2 second pre flow, as long as the post flow is still going.

It seems like that can be made to work by modifying the code to add an M5 and extend the first pierce delay by 2 seconds, but it seems like it might be more trouble than it’s worth.

I would consider buying another machine and dedicate that one to hand use or sell it.

I was having this same exact issue you described yesterday (1/3/22). I could still cut by selecting the “retry cut”, generating the code within firecontrol which essentially makes the cut it stopped on the first loop OR hit pause after each loop until the post flow stopped and then resume the program. both methods were annoying and not ideal. really the first time I had a chance to mess with this machine. I did eventually get it to work but long story short it seems to be a safety delay issue during post flow after the initial cut. I’m using sheetCAM with firecontrol and ended up changing the post and setting the pierce delay to 1.5 seconds. with sheetCAM you can go to OPTIONS–>MACHINE–>POST PROCESSOR. this is where you load the firecontrol post during initial setup. you can then choose to edit the post. looks like they already accounted for a difference between the first pierce time and the rest of them by using “firstPierceTime” constant. this should be right at the top. I saved a copy of the post as “FireControl-v1.6 lincoln tomahawk 1000” before making any changes and then changed the “firstPierceTime = 0” to “firstPierceTime = -1.0”. that is not a typo, it is negative 1 because further down if it is the first pierce they ADD the “firstPierceTime” to the set Pierce delay from the tool settings. Within the tools I then set the pierce delay to 1.5sec. this will allow the first cut to function at .5sec delay and the rest to use a 1.5sec delay that allows the arc to start during post flow when it moves to a new loop. these values could probably be dialed in a little more but it seemed to work great after this.

let me know if this works for you as well.

Thank you very much. I just finished a cut that took way too long with my Tomahawk 625 because I was seeing the exact same issue. I suspected that it was related to the built in cutter delays but had no idea how to fix it, and now I do.

BTW, I got frustrated with the lack of recommended settings for my Tomahawk and I contacted Torchmate Customer Support for any sort of cut chart and they zipped me right back a chart with suggested torch height, cut speeds and kerf width for various materials. There was still no mention of cutting amps, so I used the forum generated Razorweld spreadsheet for a trial and so far they’ve worked pretty well (mine is a 40A cutter and the Razor is a 45A so they’re close enough alike apparently). I just made the nicest cuts that I’ve made so far.

ETA: I just started cutting a piece using your recommended settings and they appear to be working well - the table continues to cut loops like it’s supposed to without any intervention on my part. Thanks again.

Just curious if anyone has tried setting the machine to grid setting. #8 page 17 in the manual.

Capncrusty, any chance you can share the cut chart you received from Lincoln? I’ve been using a 625 and have experienced all these same issues. Been fighting the post flow issue for a while now like Jajensen89 described. Thanks Jajensen for the tip by the way. This chat line helped once I made the -1 pierce delay change to the post, but I’m still issues on my second cuts with the machine torch not firing.

I never could get my Tomahawk 1000 to work right after paying $2500 for it gave up and bought a Hypertherm. Now just use my Tomahawk as hand held torch.

Update. I found out today that my machine torch was the culprit with my cut errors. I switched it out with the original hand torch, and now cutting subsequent cuts perfectly. Sometimes it’s not what you think I guess. It is what it is.

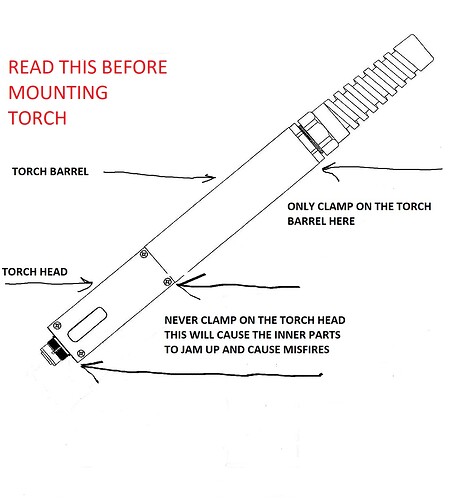

Just so you know a machine torch will take more air pressure to work then a hand torch, just in case you haven’t tried that. Also you need to make sure it is mounted the right way.

Good info, thank you, my torch only recently started giving me issues so I don’t believe it was the mounting or air pressure.

I do think something is damaged internally on the torch head. Might have damaged something when changing consumables. Anybody’s guess for now.

Thanks for all the great information regarding the issues related to the Lincoln Tomahawk 1000 and the CrossFire Pro. Just finish building the table and now we are about to attempt to configure/connect the plasma cutter part of the setup. I have a Tomahawk 1000 already, I don’t have the CNC torch unit yet. But I was wondering if its better just to purchase another plasma cutter at this point? It seems to be a pain at every corner when it comes to trying to setup a Lincoln plasma cutter. We will have to purchase another torch and then the amount of time that is needed to get this up and running…any thoughts? Thanks- Al

Henry, sorry I took so long to reply - been working on other things.

Here’s a copy of the settings chart I got from Torchmate.

Lincoln Tomahawk 625 Cut Chart.pdf (91.7 KB)