Ok, I know this topic has been discussed few times before, but haven’t really seen a good answer to it yet. Now that it’s gotten colder, I’m trying to keep my water from freezing in my unheated workshop…I’ve seen answers like RV antifreeze (which doesn’t seem like a good idea) to letting it freeze it will melt basically when your cutting…to even RV tank heater pads(which kinda might be a answer) I’m using a Sprayer tank as a drain tank. I’m worried about using a rv heater pads won’t really work because my tank is mostly round, so I’m thinking of using Immersion water Heater but I don’t need it to get so hot, so thought about using a Temperature Controller to keep it just above 32° F. Has anyone really tried this? or am I just over thinking and going extreme?

Woodstove in shop…

Heater in tank will work just as long as it doesn’t touch plastic walls and melt hole in tank.

@mnicolia i dont know if this would work but would give it a try…i would get a resistive heat tape designed for plumbing pipes…they have thermostatic controls built into them. wrap it a couple times…preferably near the base of the tank as the heat will naturally rise then i would put a water heater blanket around it. I bet that would solve your potential freeze possibility…that is how i keep my water well pressure tank from freezing.

Maybe something like this would work…? They are safe for plastic. Might need more than one.

If you leave the water in the table, you might be able to just remove a few slats and lay several of these in the void.

Farm Innovators Model W-409 Submergible Bucket Heater - 1000w (ruralking.com)

Buddy of mine has a plasma table that’s a little bigger than a CF Pro in an unheated pole barn. He’s the king of K.I.S.S. Has a cheap oil radiator heater under the table and covers the table with a canvas tarp. Diy heated tent. Been doing it for years.

He and I may be related!

It’s my first Winter with mine, but my plan is tarp cover. Here in Southern Indiana, my 40 x 50 garage floor usually hovers around 40F because I get temp up to 60-65F at least every 2nd or 3rd day using my woodstove.

Keep it at that temp for 5-8 hrs before going inside and letting the fire go out. Floor picks up enough to keep from dropping to ambient temps.

Ceiling fans help warm concrete floors to.

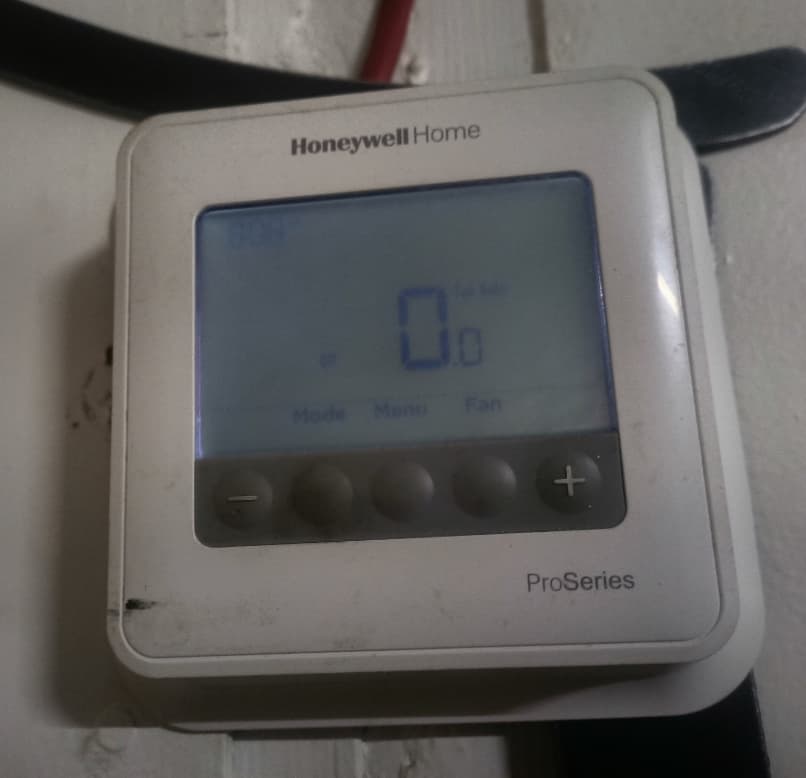

This is how I go about it.

I let it freeze.

In the sheet metal shop I started at they didn’t heat the shop and I got used to it. If I’m working in there for all day I might turn on the high eff gas furnace and heat it up to maybe 4.5c.

The temp you heat your shop to is colder then I keep my at when I am not there. You tolerate cold way way better then I

I turn the heat from 50 up to 62 and keep my coat on.