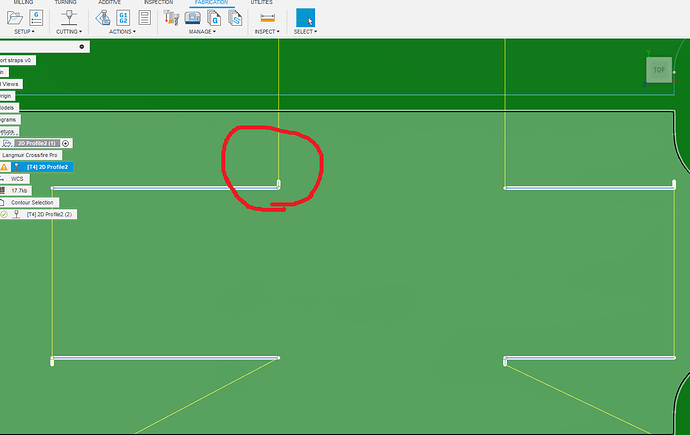

I didnt pick up on these little, what look like lead ins, on my toolpath until I went to cut it. Lines are drawn straight as I am using them as bend lines. So why did they cut this small lead at the beginning? No lead in/out, center compensation, no smoothing, no optimization…

That is the pierce clearance. You need to set it to 0 when cutting single lines. Actually I always set it to 0.

3 Likes

Ok, I see that mine is set at 0.04

What exactly is this? I dont see an explanation for what it is.

Pierce clearance is something that is completely unnecessary for plasma cutting. It seems to be a holdover from milling operations, where you want to start your tool at a safe distance from the material before moving it into the cut path.

2 Likes

Thank you for clarifying.