Like to help if I can. May want to weld a few coupling nuts on the bottom ends to tighten the plate in place. Just to be safe from side loads on the keystock screws.

Pretty sure I told you I do have that 4 way die x 32" for sale. My old timers is kicking in.

I’m going to get some 1x3x30" AL bar stock, cut it into 6" sections and mill it. Seems perfect for my limited milling experience.

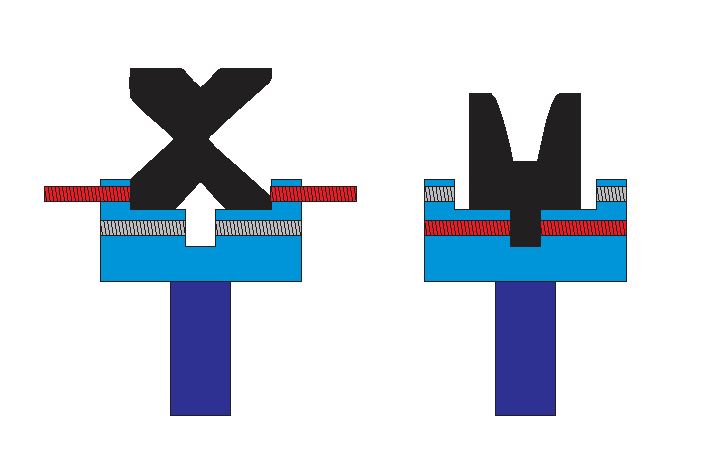

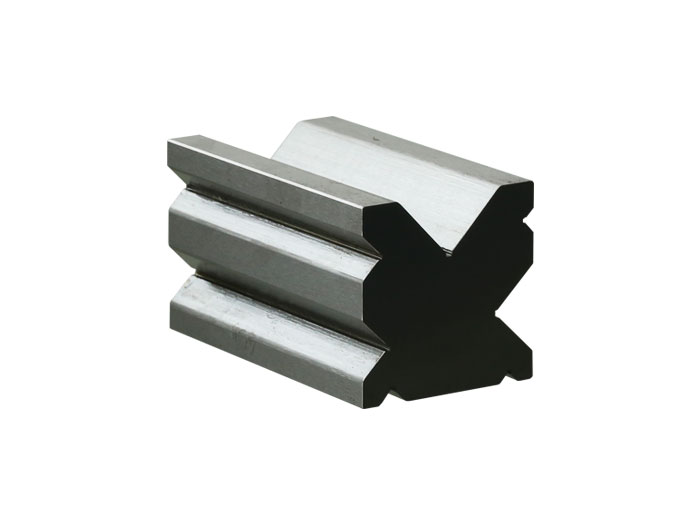

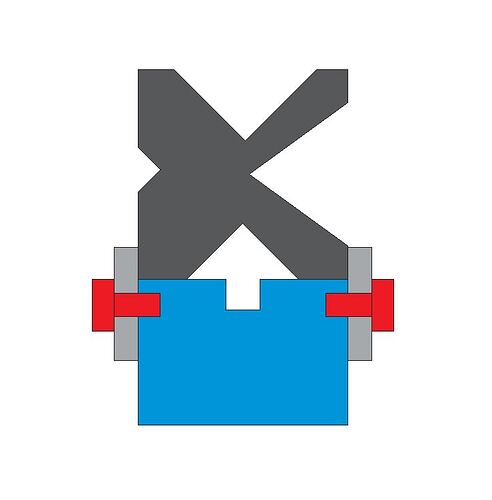

If I were to design my own lower tool holder, it would be something like this, which would hold both dies without the need for extra plates and holders. This 4 way die is designed to be always centered, while some dies have multiple grooves in each side which would need adjustment, but with this die, that is not necessary. just my .02

Interesting, I didn’t know that about dies with multiple grooves on same side.

Another possible solution is to simple bolt on side plates, if the base is 60mm, and the 4 way is 60mm, then the threaded holes in the side could be used to bolt on two side plates. something like 1/2" x 2", CR or even better 7075 alum, countersink the holes and some SS torx. The threaded hole are metric or standard?

this is the simplest solution.

6ft of .500x1.500 6061 from mcmaster is $50 # 8975K42 I think the factory risers are milled from alum. No reason to take them off that I could see, and still fits all the factory tooling.

They are made from steel with very tight tolerance. They almost snap on.

Is the machine bed also 60mm wide ? the same width as the 4 way lower?

The machine itself is 60.89mm. The 4-way langmuir die is 60mm.

thanks for that info, their mill tolerance in china must be 0.0350393701 (.89) ![]()

Thats the Normal way Die makers make them but the cost of that would be 10 times or more than their current Langmuir die holder. Langmuir designed their holder to be economical to buy from China.

Cant bend 1/4". Looking for am explosion. Maybe 11 ga. but Langmuir needs to answer your question.

That will work too.

The extreme goose neck is the heaviest die they offer, sam said it will definitely handle thicker plate. My first thought was that is would deflect, but after looking at it, the girth and width is heavy duty. obviously depending on the lower die used.

It will deflect a miniscule amount with 1/4" - enough to cause a couple tenths of a degree of angle difference, but that is very easy to compensate for. I would not use it for 3/8" however. The standard, gooseneck, and heavy duty punches would be better for that thickness.

Thanks for clarifying that Sam ![]() You might want to update the tooling and punch guide PDF to include max material thickness for each punch, and to take it a step further, max material (mild steel, SS, alum) for each punch. Probably some finite analysis cad data would give you most of that .

You might want to update the tooling and punch guide PDF to include max material thickness for each punch, and to take it a step further, max material (mild steel, SS, alum) for each punch. Probably some finite analysis cad data would give you most of that .

When you have a minute can you tell me the exact width of the press brake slot to hold the Accute dies in place. I am having some Accute dies made and want to be sure the lower tang has the correct .