When I get home I’ll download that file and have a better look at it

It’s going to be the tight corners in the features that are missing the need to be radiuses.

A semicircle cut acutely is fusions 360 biggest downfall . When I started learning it it drove me insane until I figured out how to manage it.

1 Like

I also was reading up on THC and people having issues with that as well.

I tested mine and it came back higher than recommended:

THC-Test Report_11-09-2021_18-04 2.txt (215 Bytes)

THC-Test Report_11-09-2021_18-04.txt (275 Bytes)

I converted my hand torch to a machine torch using a post I saw on this forum as a reference. I then made a plug to go into my CPC port and have DIV box. Hypertherms have the 50:1 voltage dividers already interally, so I thought this was the correct way to do this?

I am starting to hate this machine entirely.

The THC is an issue and another mountain to climb.

Take a couple clear pictures of how you have your THC wired and start a new topic.

Try to used the DXF I posted earlier, can you get it you complete the toolpaths?

Huge learning curve to all this.

I struggled for quite some time before getting it .

1 Like

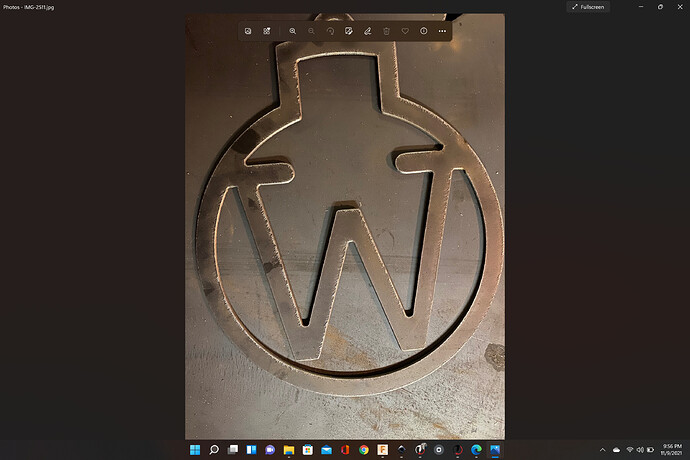

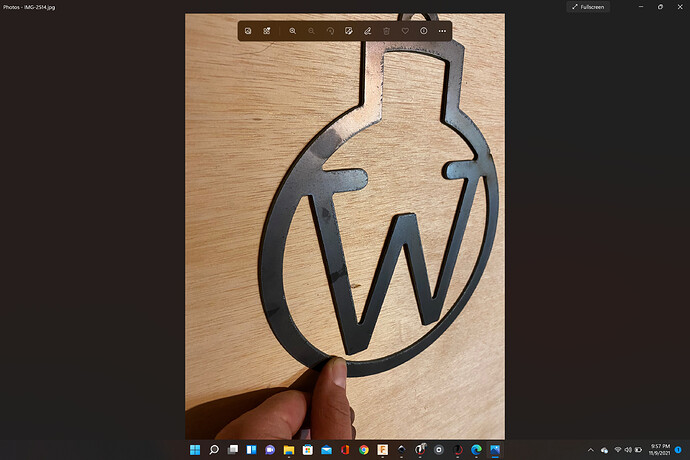

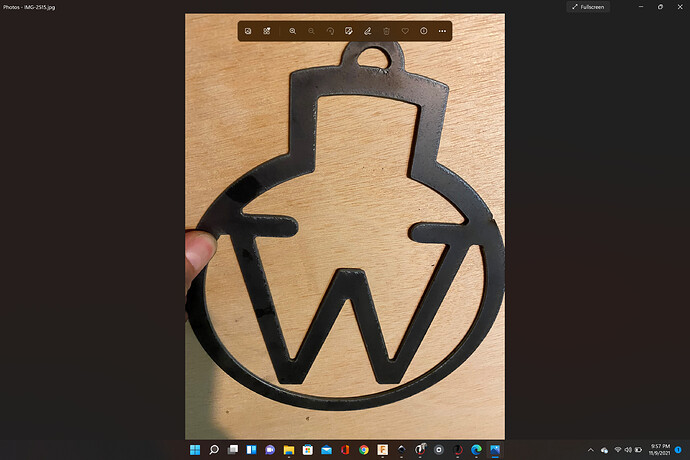

I redrew an ornament and then also sized it down just for a test piece. I changed the fillet rad. from .0625 to .090 and it actually recognized the pattern this time. I went with a much simpler letter in a simpler font. The cut quality seems to be fair, there is a little bit of dross on the front, but the back actually looks better. I also read where a lot of people say to add .4 to the pierce delay on Hypertherms, so I changed that as well. I am thinking the dross has to do with my live voltage issue now? I am using 45 amp consumables, I have an air dryer as well as a filter/regulator coming off of my compressor. My shop is very small, so I don’t have a ton of line in between my compressor, to my air dryer, then to my cutter. This has been quite the learning curve and it just seems like its one issue to the next.

1 Like

Definitely a part of it. Surely that will be solved soon too.

As long as the air has a chance to cool off.

sounds like you are most of the way there now.

Having parts you program coming off the table is a pretty satisfying result after all the challenges.

2 Likes

Again, I really appreciate the time you’ve put into helping me figure out my issues. I am pretty blown away by the community support aspect of Langmuir. It has been a really good resource for me as well as encouraging. I have been so frustrated the last week or so trying to get everything dialed in just right and to product quality parts that people would want to spend their money on.

1 Like