Long post, problem solved

OK, I took my little Hypertherm apart and wired in the on/off control cable to the switch inside. Used a DVOM to test and make sure it was reading open/closed when the handheld switch was pulled and it was. Mounted it to the torch holder and plugged it into the on/off switch port in the control box and programmed a 5" straight cut and hit the go button. It did not fire the torch, it did run the program. I took the torch off the Z axis and disconnected the on/off control then put the torch down on the work piece and pulled the trigger by hand and it fired and pierced the piece of steel.

Then I took one of the spare wires that fit the on/off port on the control box and plugged it in and hooked my DVOM to the red and black wires coming out and set it to auto range DC volts. With the machine on and laptop plugged in it read 0.000v, I manually switched on the enable for firing the torch and hit the fire button and the meter read 0.000v. I can hear the relay switching on and off in the circuit board and toggled on/off several more times, no voltage at all on the on/off coming out of the control box. THC was disabled.

I moved the DVOM test leads to the circuit board connector for the on/off torch connector. With fire control not open all the led’s are green on the x,y,z axis boxes and the pc port with one red led on for the THC. When i open the fire control 2 yellow led’s start to flash and 1 other red one starts to flash on the THC board. The DVOM reads 0.000v. With THC disabled and manual fire enabled when i hit the fire torch button I hear the relay click, the 2 yellow led’s keep flashing, the red one on the THC stops flashing and the voltage on the on/off still reads 0.000v.

I took the relay out and checked the pins, set the DVOM to ohm’s and installed the relay. When commanded to fire the relay clicks and there is continuity on the torch control on/off like pulling the trigger. So I reinstalled the gun onto the Z axis and still had my DVOM connected to the 2 wires inside the control box for the on/off torch control. When I pushed the connector into the control box for the torch on/off the plasma fired. Nothing in the fire control was enabled for it or programmed. When I looked at the screen the enable switch for torch fire was off and the fire torch button was blacked out, THC was disconnected and my DVOM showed O.L.

I switched the plasma off to stop the torch air. Waited 30 seconds and turned it back on. Nothing happened. I programmed a 5" straight line cut with the torch head 1/16" off the work piece and hit start program. The program ran, my DVOM showed a closed circuit 0.000 ohm’s resistance and the torch did not fire. I pulled the trigger on the torch manually and it fired and blew a hole in the plate while still mounted to the Z axis.

IT’S FIXED!!!

They should make a sticky about this. Maybe it will save someone a weeks worth of time.

I pulled the cover off my Hypertherm, I disconnected the round plug from the control box and then removed it from the box. I plugged it into the connector for the control wire to the Hypertherm and then ohm checked each wire from end to end. With my Fluke 88 meter it read 0.000 ohm’s on both wires through the round connector. I plugged the wires into the control box and left my Fluke connected under the clear rubber covers at the connection inside the control box. When I loaded a straight 5" cut program and hit the start button, the relay clicked, the meter read 0.000 ohm’s when the relay closed, the table ran the program and the plasma did not fire.

I moved the meter to the connections inside the plasma at the scotch locks and ran the program again with the same results. Meter read 0.000 ohm’s and the torch did not fire. I reached up and pulled the trigger on the plasma and the meter showed 0.000 ohm’s and the plasma fired and blew a hole in the plate. Ran the manual torch control, meter read 0.000 ohm’s, torch did not fire.

I took a pair of pliers and grabbed the round connector on the back side where the nut screws on to hold it in the control box and pulled the connector apart. The torch fired as i was separating the connector briefly. When I tried to reconnect the two together I squeezed pretty hard on the pliers to the point it took good force to push them together. I restarted the 5" cut program and the torch fire and ran the program, did the post process and then shut off, I ran a second program in the opposite direction that was longer and the torch fired and ran the program.

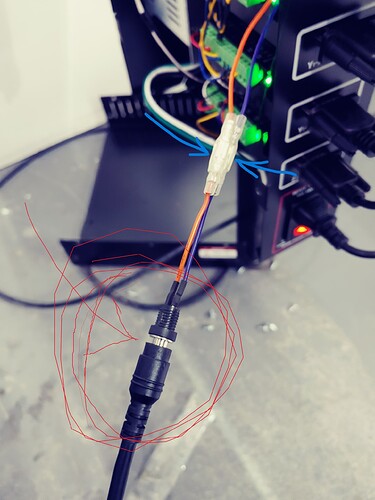

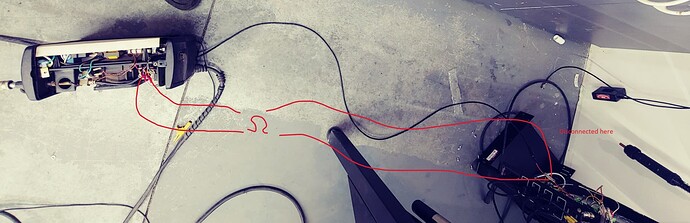

The first pic shows where the problem was at in red. The second shows where it was measured and tested good with an ohm’s test. When the meter is connected at the 2 scotch locks inside the plasma for the lead to the control box with everything turned on but the plasma main switch it reads 2.8K ohm’s. If the meter is hooked to the 2 scotch locks with the plasma main switch on it will fire the plasma torch. I have never seen any non powered circuit that had a 0.000 ohm’s reading but did not work. When it was switched off it showed O.L. and triggered on read 0.000 ohm’s at both the beginning and end of the circuit. I’m not sure I’ve ever seen or heard of something like this happening.

AT ANY RATE IT IS FIXED!!