As far as the Springback/backlash, Yes. Anything that does not have much flex should have the springback/backlash set to “0.0”, that would include any plate that is probably 10 gauge or thicker. Now there could be some flexing of 10 gauge if the slats are getting excess slag/dross on them or they are becoming worn.

Something else to think about that I haven’t checked yet. The small Crossfire table has a cantilever gantry arm for the X axis, that can only be so solid. My guess is that there is going to be some flex of that arm when it comes to spring back setting, especially out near the end.

The more I learn about this thing, it’s becoming clear that I need to look into the smart voltage thing.

I got out into the shop today and did a few measurements for kick and grins…

I have included a photo and the gcode of my setup to test at the spring back at the extreme positive X axis.

At the torch touch down when the IHS opens there is .003 downward movement of the plate and .019 upward movement of the X axis arm. One thing that is interesting is that to achieve .060 clearance between the torch and the plate at cut height I had to add .025. One other thing after adding the .025 in the IHS command and measuring the torch height at the pause line 13 of the gcode, I could slip a .0015 feeler gauge between the torch and the plate. I have a thought on that situation is that the plate is a little narrow and it is being pushed down a little more on the right (under the torch) side than on the left (Under the dial indicator).

Modified cut height test.tap (244 Bytes)

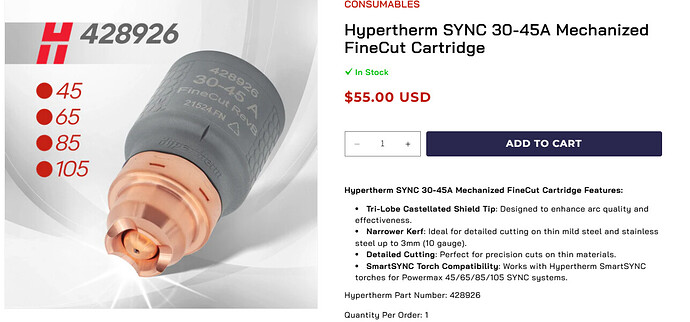

First off that is the wrong Shield on the torch. Thats for hand cutting.

Is that piece 1/4"? if so your not getting spring back from the piece flexing. I dont have a cross fire but I think the torch mounting would be the same as the XR. Its only the weight of the torch pushing down on the piece. Are your slats seated firmly? Is something loose some where?

I would put a larger piece on there and check again.

Why are you using a hand cutting drag cartridge on a CNC torch?

Jim is correct, it is in fact a Mechanized Fine cut cartridge for the Sync 45.

The whole test thing was just curiosity on my part, I have only cut two things since I’ve owned the table. I just cut the hole today for a larger drain, I should be back online by the weekend. I don’t have a problem that I know of.

@Knick I don’t believe anything is loose, and the slats are seated good. You are correct in that being a 1/4" plate. I’m with you on the plate not flexing, I have one larger plate but even though it is new it is not as flat and does not set flat on the slats. I can’t tell you what is flexing it just seems it’s the slats or… .003 is not much flex. Everything on this table compared to my lathe or mill is flexy. I believe it is just one of inherent things that the small crossfire table has. The gantry arm for the X Axis is only supported on one end, there is no way that arm is not going to flex, as I just proved with my test. I’m not sure how anyone can get good cuts without THC control. But like I said I’m just learning.

I appreciate your input.

Tim

Ok I was adding the .003 and the .019 together. Guess I did not really understand how much movement you had.

so when you set cut height do you do it with that shield on? I cant tell in the pic if the tip is flush with that shield?

Hypertherm designs all their torches to be measured to the machine shield or deflector (not the drag shield). Somehow they have it all calibrated that way.

Well then excuse me. Because I have never seen that cartridge before. I am guessing they built it that way to get rid of any blowback that may happen.

They are just trying to trip us up George! Don’t you know it!

I see that now. Also just found out that the Eastwood Versa cut 40 cnc plasma cutter uses a Chinese S45 hand torch. But the machine torch is a Chinese copy S75 torch and only uses 50 amp drag consumables, I just don’t get it. I think these company’s need to do a little more research before just buying this junk from China.