This is something you’ll have to research more on your own as I could give you reasons why you should switch, and reasons why you shouldn’t.

While I’ve never owned an Everlast, I know of tons of people within this forum as well as the FB group posting the many things they cut with them. Like any plasma cutter on a CNC table, it is completely up to the end user to dial in their own cut chart for the best results.

I personally ran a PrimeWeld CUT60 for well over 4 years (2.5 years on a CNC table) and achieved what some people thought were laser-like results. Clean, sharp and squared edges, cuts with no dross, and more. And this was done with the Chinese PTM-60 machine torch using Chinese consumables. I say this as I’m aware of Everlast machines using the same consumable style as well.

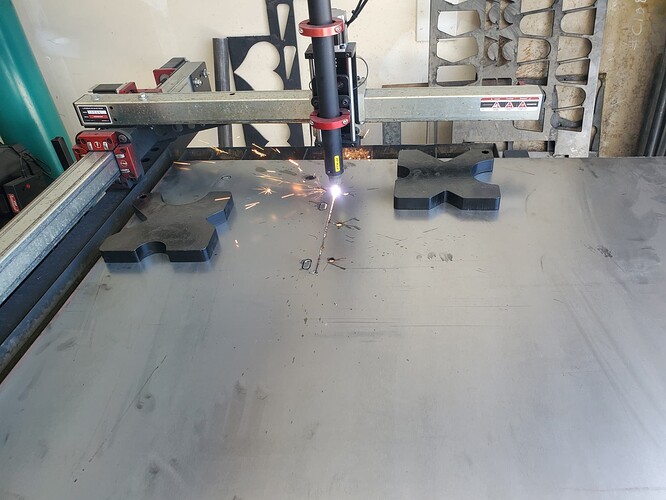

Here’s an example -

Seeing as how you own an 82i, you have a larger variant than most which means the ability to cut thicker material, as well as having more headroom for better duty cycles.

I know you mentioned having issues, but maybe someone can chime in and help with that. I don’t know if any of them were related to running DIVIDED as it’s often suggested to run RAW for THC.

So, reasons for sticking with the Everlast would be -

- Power

- Duty cycle

- Already owned (no extra money out of pocket)

- Great cut quality achievable by dialing it in

And if your consumable life is really suffering, try to figure out what it really costs you to replace them as often as you do. I would buy my consumables from PrimeWeld so they were ridiculously cheap. My replacement schedule was around 400 pierces per electrode and 400 pierces per nozzle. You may be running into pierce height issues as incorrect pierce heights can quickly damage consumables (even new ones).

This was while running a small, 30 year old Craftsman air compressor at 110v with no refrigerated air dryer.

On the other hand, you could look into buying a different machine torch type that uses different consumables. A lot of people make a clone of the old Hypertherm torch, using T45 consumables as I had one on my PrimeWeld as well when it first came out.

Cut quality was the same (not a bad thing, I was already getting excellent results) whereas consumable life went up quite a bit to an average of 800 pierces per electrode, and 800 pierces per nozzle. This difference in consumable life can be explained due to the use of shielded consumables versus that of the PTM/IPT style torch.

It only went up to reach a thousand per set when I added refrigerated air.

Here’s an example of those cuts -

Now, let’s talking about switching.

I run a Hypertherm 45XP, and I must say things were a little different than I expected. Keep in mind any opinions I share here are from having compared it to my old PrimeWeld CUT60 with UPM-105 torch.

Since I cut 3/16” quite often, I will say I saw practically no difference between both plasma cutters. Nothing stuck out in terms of cut quality, lack of beveling, etc. I did notice that I was able to run a shorter pierce delay, as the Hypertherm was quicker to fully pierce thicker materials.

The only other thing that stood out was being able to cut at a faster speed for all materials at the same 45 amps. With the CUT60, I would run a slower speed at 45 amps, or nearly the same speed as the Hypertherm but at 60 amps. The Hypertherm just seemed to have more “oomph” and that’s due to the actual higher output voltage.

Where the Hypertherm really stood out was on thin material with Finecut consumables.

Whether it’s on stainless steel, aluminum (not recommended, but I use it anyway), and mild steel, both the initial pierce and along the cut path there is a lot less heat soak due to the thinner kerf using Finecut.

Here’s a cutout of the same item, same table, same material but with one item being done with a Mechanized consumable set, and the other being done with Finecut -

And just some random parts cut with Finecut -

So, the reasons to switch to a Hypertherm (in general) would be -

- Consumables available everywhere, including locally

- Finecut consumables for thinner material

- A cut chart to reference (use as a guide, you should still create your own)

- Actual output rivals that of competitors rated at the same “amp” rating

- American-made

And lastly, the Sync models.

I’ve never owned a Sync, but a personal friend of mine owned and ran a Hypertherm 65Sync like a dog. I am talking 8-9 hours per day, an average of 5 days per week (sometimes 6 or 7), for over a year straight.

He had gone from a Langmuir table and PrimeWeld CUT60 to a 5’ x 10’ STV and Hypertherm 65Sync and business continued to explode.

Most of his work consisted of thinner material like 16 gauge, 14 gauge, and often 11 gauge and his average consumable life was always between 1,800 to 2,200 pierces. Whether it was with the regular Mechanized cartridge or Finecut, he always had great consumable life.

He did often switch to the 45 amp variant cartridge though, due to a known issue with the spring on the electrode becoming stuck on Finecut cartridges. You can read about this on the forums if you so like. Otherwise, that 65Sync was an absolute beast.

The only thing it seemed to not get done as well as a 45XP is anything you’d cut at 45 amps. It’s hard to explain, as the cut quality was still great but it seemed like items had a tiny bit more dross or input a bit more heat into the material (the blueish discoloration due to heat).

Seems there’s a reason why many favor the 45XP over anything else as even Hypertherm engineers will tell you - the 45XP does things at 45 amps better than any other Hypertherm.

The unfortunate thing is, you’ll only be able to find a non-Sync machine in the used market as they were officially discontinued over a year ago with the 45XP being the last model.

So, depending on what you do, you might find value in making the switch.

If I was only cutting thick material all the time, and didn’t care for signage, I may have stuck with my PrimeWeld CUT60. I’m a hobbyist, and I don’t care to make signs so thin material normally sits on my wall unused. I bought my Hypertherm because opportunity arose, and my table was making me more than enough money anyway so I saw it as an “investment in my shop”.

Hope this helps.