I finally made my first cut yesterday (a circle) and was pleased. I have the razor 45 with stock consumables, Sheetcam and FireControl. Today on a more complex cut, I’m not getting as clean of a cut as I would like. And cutting outside the lines…when lead in on inside. See pictures… I am cutting thin 26 gauge zinc coated steel (only thing i could get locally today). Is THAT the problem? Is it possible to get a clean cut with my setup? To my eye it seems as though the pierce delay is set high, but I have it set to .01 seconds. it just looks like it set there for a second. The pierce height is set to .15. I’ve tried the different feed rates (currently at 200ipm). Any ideas? Thanks in advance.

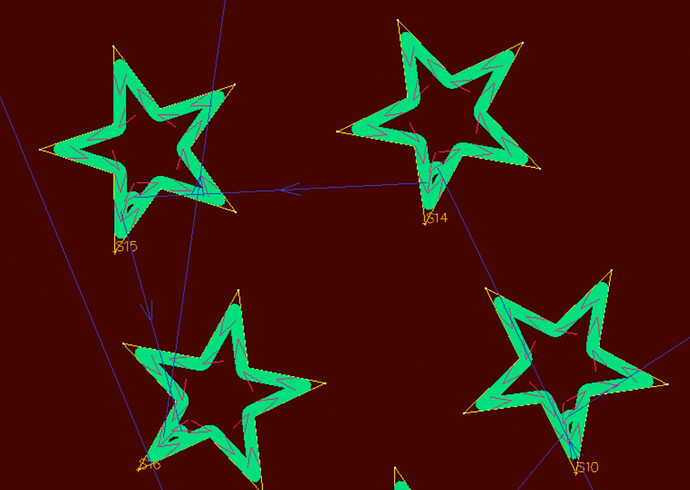

Lettering is complicated, but, since you showed the toolpath from SheetCam on the stars, I would edit the Starts so that the start is on the inside most part of the star, where the angle is > 90 degrees. There you have more room to burn into your piece without compromising the points of the star.

How many amps? I would try maybe 25 or so with 200 ipm, try on small pc, report back

i tried as low as 20 amps and 200ipm. even though the pierce delay is set to .01" It still seems to delay when piercing…

.01 may be way too short. Try .2 that works great for me under 3/16 thick.

Now I have noticed some programs seem to add extra delay. It may be a heat issue with torch, between piercing.

.5 gave me too much “overburn” and led to arc lost at times.

Remember it pirce delay is the time between “pulling trigger” , piercing and then moving. I thing the short delsy is not letting it establish a hole and arc