Super new to this cnc thing, just in the process of assembling, i ordered the thc add on with my table and was curious as to if anyone has hooked it to a thermal dynamics cutmaster 82 and what was involved for the tie in. Would prefer to not fry anything on either unit. Any insight would be awesome! Thanks for your time

I use a cutmastet 82, the hook up in the Langmuir directions are spot on. I’ll try to get a pic of my wiring for you. One thing to know with the thermal dynamics (TD) is the cut heights and pierce heights are different than a lot of what I see others running with razor welds or Hypertherm. If you’re running the hand torch you will have to run a minimum pierce time of I think 1 sec for the initial fire off. The TD machines have a purge process the initial fire and won’t let the torch fire immediately. I run the machine torch and it bypasses that. I also run shielded consumables and have great results.

Here is a post from when I first started and was having trouble. Might save you some headaches. I use fusion and would have to go in to the nc file after posting it and manually and set the first pierce to 1.3 and all other pierces in the program where book settings for the material

If you had a picture that would be great! I was a little tired when reading the instructions but it look like i would have to tie into the high voltage on the inside of the machine, is that correct?

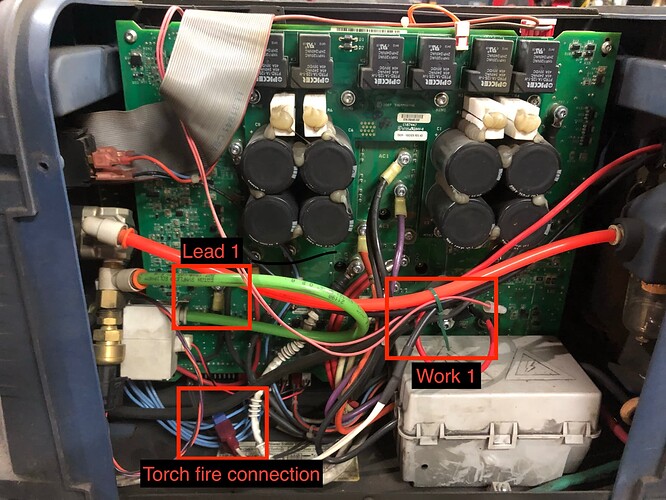

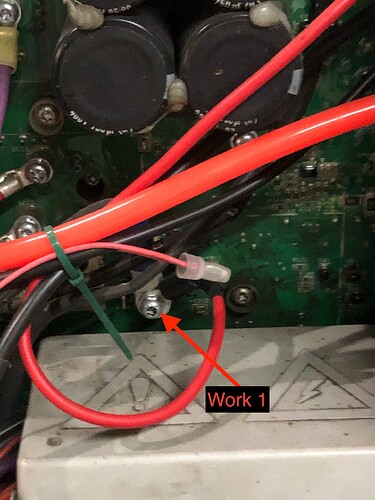

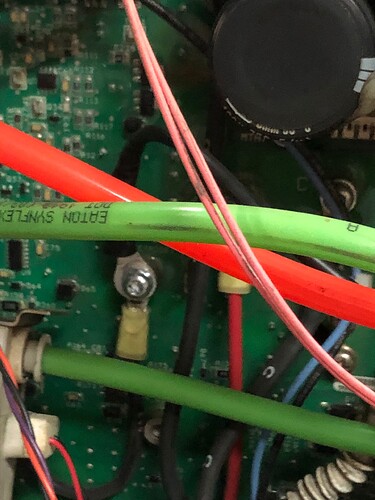

Here are some pics of inside. You do expose your self to the high voltage. Follow all safety precautions. Unplug machine and don’t mess with the capacitors and don’t do this on your welding table. Wooden bench or table is best. The red wire from VIM box goes on the terminal that is marked ground 1 and is same terminal that your ground clamp is connected too. The black VIM wire goes to electrode 1 terminal on the board and is shared with the torch lead. You will need to check the pin out of the ATC but I believe it is 3 and 4 that are the torch switch and the run back to J9 plug. You can test it without turning your machine on by using a Multimeter on continuity setting. It should beep when you pull the trigger and not beep when you don’t.

Thanks so much! You are awesome!

So, just to be clear, the two leads you have connected under the torch fire connection box go back to the pv output on the vim box? I am not seeing the harness labelled or that plug mentioned on the install, matter it is the only one not mentioned, so i am assuming that is where it belongs?

Next question, does the polarilty of the two wires on that harness matter at all? Also, you mentioned to check the pinout of the THC that being the torch height controller? And by that do you mean the vim box that came with the torch height controller? Or is that short for something else inside the plasma cutter? That would make more sense as you said to check the continuity with the trigger pulled and not.

Final question: If the Thc is an internal component of the plasma, testing the j9 plug, am I doing this testing hooked to the circuit board or unhokked from the circuit board?

Thanks for your time, i am trying to get this set up in the evenings after work and appreciate all your help!

The THC and Vim box polarity matters. Red is labeled clamp on the VIM and goes to the “Work 1” terminal on the circuit board. Black is labeled torch on the VIM and goes to the “Lead 1” terminal. You will see those labels on the circuit board.

Torch fire connection taps into the harness that goes to J9 plug and goes directly to the panel. I am referring to the ATC not THC. the ATC is thermal dynamics quick connector for the torch. Inside the machine on the back side of this connector you should be able to touch your multimeter to the back side of these wires at the connection to verify you have the correct wires before you put the supplied wire taps on them. Polarity for the torch fire does not matter.

The THC is not an internal component of the Plasma cutter. It consists of a PCB that you install in the CNC control box and the VIM box.

I will try to grab some more pics today while im out in the shop. Happy to help. I had many members help me along the way. Getting set up and learning the work flow takes a bit. I had to remind myself a few time that it is fun even though a bit challenging learning something new.

Hey i really appreciate the help so far, work has been nuts and i haven’t been in the shop much. I was under the assumption initially that the leads that tie into the harness that goes to the j9 plug had come with the thc, but now realize that they plug into the box for the cnc control. Too many late nights trying to read after diagnosing electrical problems on farm equipment = not enough focus at home lol

Y’all helped me out. Just wanted to say thanks.