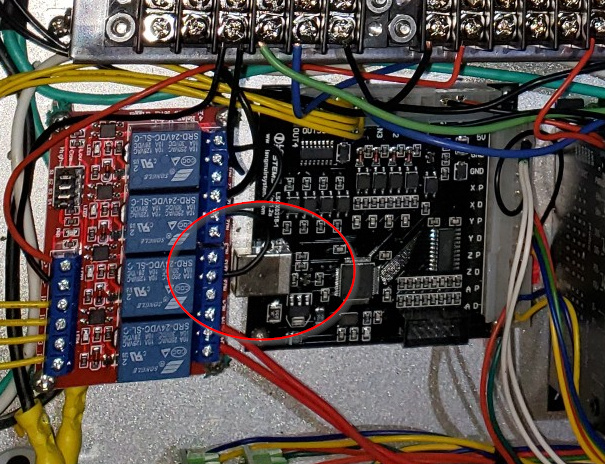

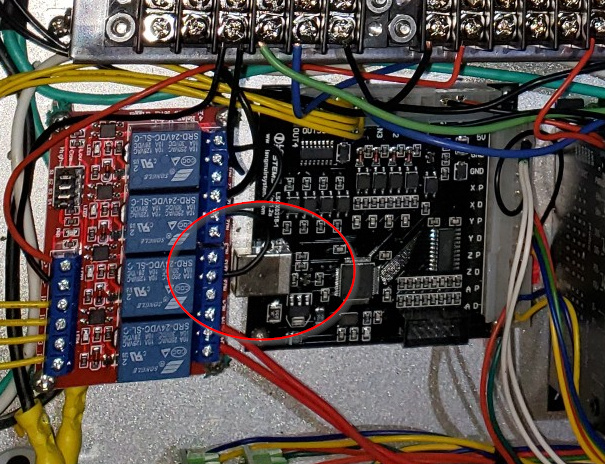

@Masimec17 can’t tell from the picture, but plugging in your USB might be a little difficult!

@Masimec17 can’t tell from the picture, but plugging in your USB might be a little difficult!

Good use of the drywall whatever they are called! Damn, and I ordered plastic screws and risers! Box of those are cheap!

This is a really cool thread…I ordered the Crossfire Pro about a week ago and have been going back and forth on the THC option…my big hangup is with Mach3 vs 4 - not sure I want to invest in something that’s stuck on Mach 3. Thinking about upgrading my pro to a smooth stepper and the TMC3in1 THC module. Both are about the same $ as the THC option on the pro, but I don’t have enough details on how the THC module from Langmuir works…so I think I’m going to wait until the table gets here.

You wont need mach3 with the pro langmuir has their own software for it.

Is that the firecontrol software…know of anywhere to get details on it? I guess I missed the part about Mach 3 not being in the mix on the pro…thanks for info!

Seems they are being tight lipped about it. Just that it exists. There’s a special forum for pro users there might be more info there, I think you have to have apro on order for access

Ping Support (or @langmuir-daniel) and ask them to add you to the Pro group (and get the Pro tag added to your name here). After it hits the streets there’s going to be a bunch of stuff brought up by users which won’t be of any (or much) interest to basic or XL model owners on how-to do things that will likely end up there instead of creating tons more questions about things that the other two models don’t support from people who miss that the issue is being discussed in the context of a Crossfire Pro.

@langmuir-daniel can you add me to the pro forums?

Did you get your proma THC running? Which one are you using?

What do you have wired to the 4 relays?

I currently just have torch on/off wired, but I’m going to wire in a pump to fill the water table, and and electric ball valve to drain it… someday… I’m not using the proma, I’m using the robott3 one in my writeup…

Any issues running the Proma SD on the controller vs the plasma cutter and using 1:1 arc voltage? It looks like many people have done that. My plasma cutter has cnc ports on the back for on/off, arc ok, and arc voltage @ 1:1.

Thanks for the info on the THC wiring info Dicky

Wow! This was an exciting read along with the write-up.

If there’s really no need for the linear rail arrangement to support the cantilevered arm (please chime-in with further advice on this),

I essentially already have everything needed for this build right here in the shop (power supply, stepper driver, buck converter, 24V 4-channel relay boards) All I really need to buy is the Z-axis linear actuator and the Compact THC. My version will utilize a seperate cabinet for the complete z-axis system electronics.

Found this actuator on Amazon:

https://www.amazon.com/gp/product/B08CRFR39Q/ref=ox_sc_act_title_1?smid=AIVOOTLDDRLTB&psc=1

What a rabbit hole, this Plasma table thing!

Thank you very much gentlemen, for sharing this project!

Hahaha! …interesting, I thought I was the only engineer that used green Rawlplugs as circuit-board standoffs!

Well, you don’t need the relay board, the existing torch relay works just fine, you just need to add a 5V power supply to isolate and repower the 5V for the relay and THC interface. You can also roll your own Z Axis using Open Builds tracks and wheels. See Finally completed my CrossFire mods - #11 by TomWS and an earlier post that talks about the Z Axis mod.

And, Yes, I agree, this thread is a VERY good source of information.

Trying to wrap my brain around Proma or THC3T controllers… Something I’m not getting!

I don’t know anything about the Proma THC but I REALLY like the THC3T controller! Having said that, the one thing you have to accept is repackaging it. That’s not to say the package is bad, it’s actually a very good quality package, but it is not splash proof and the ‘Divider Board’ is this fairly large orphan to the main controller and needs to be dealt with.

I found the control parameters easy to tune and seem to be rock solid.

OK, think I got it now

So I’m budgeting maybe another US$650 to do Floating Z, THC3T-02, KSK-AP-4H sensors, a decent enclosure and nice connectors/fittings

Looks like I can do  it in stages,thankfully!

it in stages,thankfully!

https://www.amazon.com/gp/product/B07SJM467C/ref=ox_sc_act_title_1?smid=AQJQWHRODJ0FC&psc=1

https://www.automationdirect.com/adc/shopping/catalog/sensors_-z-encoders/inductive_proximity_sensors/18mm_round_harsh_duty/stainless_steel_factor_1_sensing(18mm)/ksk-ap-4h