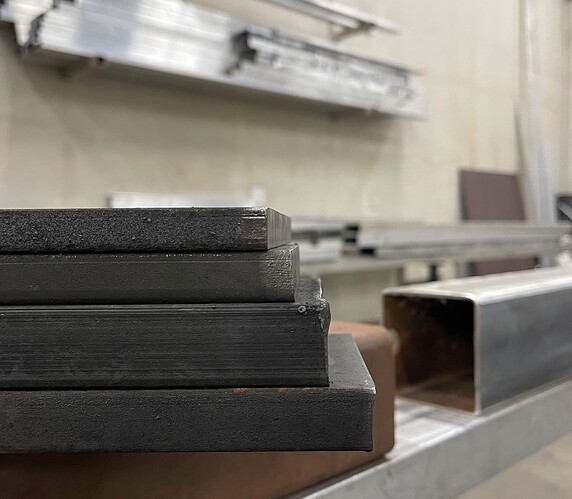

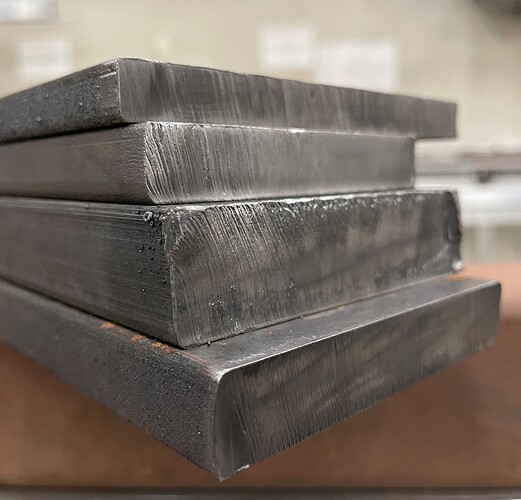

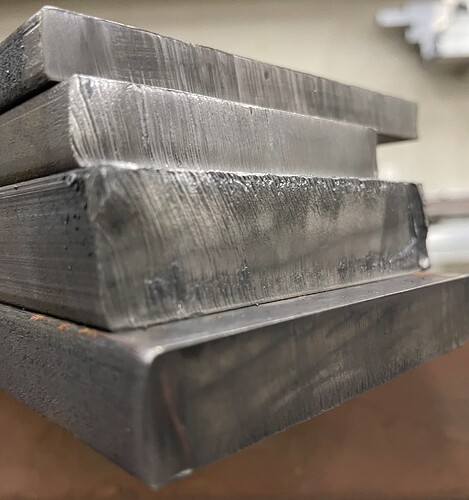

So after realizing the machine torch on my brand new Razor 45 is likely out of spec. ( I think it has been machined bad and the tolerances are out of spec. ) It will not cut with out beveling with no consistency. So for the heck out of it - I wired up my old Hyperthem 600 and changed the machine torch mount to handheld. I just really wanted to see how far I could push the 600 to in thickness. Now while the cut quality did decrease as the material thickness went up - it did do it. But here they are - from the top down - 1/2" - 5/8" - 3/4" - 1". I did all of them with an edge start. Now mind you this hypertherm is a 15 year old machine with old technology

Now when I say the Razor was cutting bevels when ever it wanted - that was from 3/16" - 1/2" material. the Bevel at it worst was 6 degrees. The hypertherm even on 1" wan only .5 deg bevel

That hypertherm 600 is a way better machine than the razor weld is.

And you can buy a Duramax retrofit torch kit for that unit for about 800 bucks. You’ll gain consumable life by 55%.

It’s great that you found your problem.

It also makes a really good point that when people are looking for economical machines instead of buying brand new economically priced machines buying used hypertherm equipment is another consideration.

yes - I had a feeling it was the machine and torch - the variable was way to great with it. I will run the 600 for now till I get a new machine. I knew guying the razor cut with the table was a bad idea. I know I should have just spent the money and bought a hypertherm - But I cheeped out and its going to cost me for doing that. I am just glad I had another machine to test to prove my theory , even if it is an old machine. I am looking at the new Hypertherm 65 and 85 now. just do it right now. I don’t want to buy another machine and then be underpowered later. Just spend it now.

oh you are so right - and that was part of the reason for posting it - I should show a real side by side comparesent. But I am not going to buy a 45 am hypertherm to do a VS comparisons - I will buy a 65 or 85

https://www.hypertherm.com/Download?fileId=HYP116299&zip=False

Check out this torch upgrade for that 600. You might be able to just switch it over so you’re using the new Duramax consumables and run that thing for a while and spend money on a new plasma later.

750us is the cheapest I found it so far.

I was just looking at that - I like the guys at Baker - I bought my Lincoln 260 MPX and Active 8 from them. Great guys. I may just order that. I guess 750 is cheep to keep running right now VS 4 or 5 grand for a new machine

I am about to buy a Powermax600.

The price negotiated will be cheap enough to buy a new machine torch and still be less than a 30xp.

But…… I test ran it and it was not impressive, snotty slag, inconsistent kerf and hardly edge cut 3/8” plate.

I’m betting I have issues with worn consumables and water in the air….

But new consumables for the obsolete torch have to come from an online source….

Does anyone have experience with a Powermax 600 on 3/8” steel?

I am running and old powermax 600 on my table - I cut 1/2" all the time on it - the dross is heavy but taps right odd with a little tap. 3/8 is a breeze. I do edge start on 1/2" though. I did have a 1650 powermax on the table and it was a monster. But decided to sell it ( I got a lot of money for it ) The consumables ate no longer available on the powermax 600 from Hypertherm - but are on Amazon ( aftermarket ones ) them are the ones I am running and work great. The price has to be cheep on the 600 thought ( 500 600 bucks ) - My buddy is running a 81! and loves it and the cuts are outstanding. I am considering going to the 102! on my table to get the capacity back. Hope this helps

With the Crossfire Pro connect directly to the torch pigtail? Any internal wiring mods required?

I opened up the case and tapped in to the trigger wirers and connected them to the pigtail

I see your post is a bit older, but I have the same machine. Do you have a list of cut speeds and settings? I am cutting 14ga steel at 61 ipm at 36 amps with some dross that knocks right off. I cut 11ga at 42 ipm at 40. I have run nothing but fine cut consumables since that was what came with machine when I bought but will be moving to standard consumables to try them out.

I have a project to cut a ton of 2’Ø standard ANSI 165lb flanges out of 1/2" and was curious where to start. Your 1/2" cuts look really good.

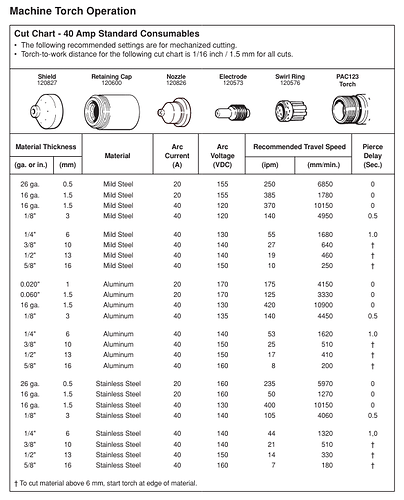

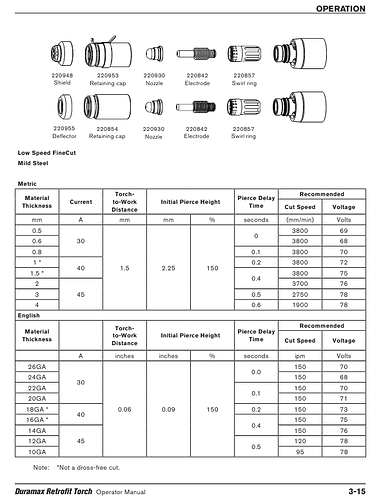

Here is the cut chart from the Nov 2013 dated manual:

Hypertherm Powermax 600 manual.pdf (2.6 MB)

This one has a whole bunch of cut charts including the FineCut:

Hypertherm 600 manual.pdf (6.1 MB)

Thanks for the charts. I have the first one shown. My machine does not cut anywhere close to these speeds. I am almost half on all of these. I am starting to think my machine is only running at half power.

That second manual (the large file) was dated about a year earlier (2012).

Have you confirmed what your actual cut height is?

If not, consider running this gcode file from @Phillipw

cut height test.tap (224 Bytes)

It will go thru the IHS (initial height sensing) and then go to the cut height of 0.060 inches and stop. Measure and see if you are at 0.060 inches. The torch will never fire with this code as it never gets the command to fire.

Here is the actual g-code so you can see there is no M3 code that would turn on the torch:

(v1.6-sc)

G90 G94

G17

G20 (Units: Inches)

H0

G92 Z0.

G38.2 Z-5.0 F100.0

G38.4 Z0.5 F20.0

G92 Z0.0

G0 Z0.02 (IHS Backlash)

G92 Z0.0

G0 Z0.15 (Pierce Height)

G4 P0.5

G1 Z0.06 F100.0 (Cut Height)

M5 M30

(PS100)

Notice it also includes the “springback/Backlash” of 0.02 inches. If you are doing this test on 10 gauge or thicker, you really don’t need any springback so adjust accordingly. You will also notice, this gcode file does not include the M3 (turn torch on) command.

I have not checked it. Sad to admit, but I just assumed a correct torch height. I will run this and measure. Thanks for the advice.

I finally got this checked. It measured 0.065 which is pretty close.

I also tried cutting at 40 amps to achieve the speed in the manual, all I got was some fancy etching and destroyed an tip.

Post your gcode file. Just attach it to your post. If possible, post a video clip as well but that will need to be posted on YouTube or similar service and then post a link here to the video.