I know there have been a number of questions in the past regarding cutting SS but I figured I’d give it another shot.

I’m using a standard Crossfire with a Hypertherm XP45, straight air, super dry (intercooler on compressor, 4 different water traps, desiccant drier right before the plasma cutter). I’m using fine cut consumables on the XP.

I’m cutting a lot of 18G 304 stainless with anywhere between 9 and 11 pierces per piece. These are small pieces with a fair amount of detail so using the fine cut consumables.

I feel I’m still getting a bit too much dross on the underside, I’d like to reduce that if possible.

I’m running 225 fpm on these parts at 40 amps.

Realistically how much run time and pierce count can I expect from an electrode and nozzle?

There is a noticeable increase in edge jags and dross when I hit about 500 pierces. Total torch time is around 23 min or so for 600 pierces .

I’m also going to fire off a note to Hypertherm to see what they say.

Thanks much folks, much appreciated.

Brad

What cut height are you running ?

Did you come up with these parameters with experimentation?

Have you tried using the cut charts in the manual?

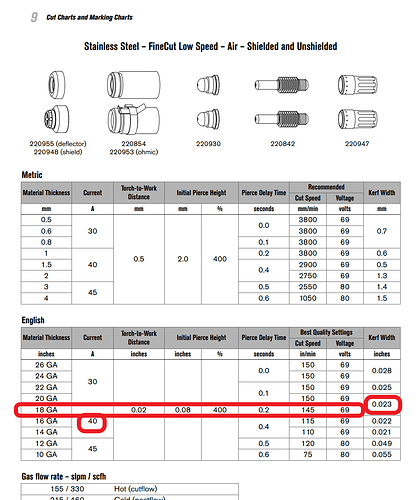

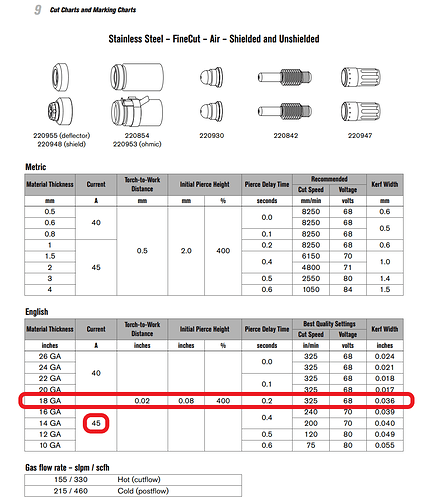

take note that the cut height of stainless is 1/3 that of standard cut height and that the Pierce height is 1/2

running a higher then recommended cut height will always reduce consumable life.

Tin! I was hoping you would chime in. Much appreciated.

I’m running much closer to the second SS chart than the first. I think I’ll try the first set even though it’s half the speed. I’d rather that the cut time be longer than have to do all the clean up afterward. After looking at the way I have the “tool” set up in Sheetcam, it looks like somewhere along the way some of my settings got changed.

Good info on the cut and pierce height differences for SS regular mild steel.

I’ll define another tool and make some test cuts tomorrow.

BJ

Ensure your water table is chock full and as close to submerging your work piece as possible. I’ve personally found (I cut a bunch of 10ga for the crosses I make) that the dross is just part of the game if you’re cutting with air. Get a GOOD set of files and some soft jaws for your vise for cleanup. There are some angle grinder wheels that do a good-ish job of knocking the dross off, but they burn up pretty quickly.

These guys:

Thanks for the tips Tin, I redid my “tool” for 18G SS in Sheetcam using .08 for pierce and .02 for the cut. I also had to increase the pierce delay to .8 to keep from timing out.

I dropped the feed to 145 as suggested and have the torch set to 40 amps. Man what a difference that made. Even using a nozzle and electrode that have over 700 pierces on them the cut quality was better than anything I’d had before. A new electrode and nozzle made it even better. I’m using a clamping device I cobbled together and Benchmark Abrasives 60 grit ceramic flap wheels to do the final clean up and put a nice brushed finish on them.

The edges are fine right off the table, no jaggies anymore.

Couple of points, MAN! does the water table get gunked up FAST.

I’m still tweaking the lead in length trying to eliminate any lead in pierce marks. They are really small now but I’d like to get rid of them altogether.

apynck3l, thanks for the tips, I always run the table as full as I can. Even made up some Alu shields to keep the water in the table! I’m going to check into the sanding discs from Benchmark, they look like good ones to have on hand. As mentioned above I already use their flap discs. Good company to work with.

Interesting note, my table pretty old, maybe one of the originals (I bought it used 4 years go or so) it came with an Alu pan, not SS like they do now. The pan had lots of pin holes, probably from the previous owner not always filling the table. Regardless, I needed to make some cuts so I hit the outside of the pan with good ole Flex Seal. Bought a small can and coated the entire outside of the pan up to the lip. I’m not had a leak since.

ESPECIALLY from cutting Stainless!! You like the nice black soot? ![]()

that is great!

So where are the pictures of what you are making ?

Tom, yes, it was a surprise how much it kicks up. I wear a respirator now.

I’m cutting 2’ by 2’ sheets, we get 30 to 36 pieces from each. Each piece has 9 or 11 pierces.

Tin, I’d need to get permission from my daughter to post them. They are her designs, I’m teaching her how to do the process start to finish. She can do it but I’m much faster at set up and running. They have limited time as they do art fairs almost every weekend. Normally they crank out all their stuff over the winter but this was a new idea for them.

They are reluctant to post much stuff as it always gets knocked off.

Another issue has popped up… I need to refresh the compressor. Either a totally new compressor or a new compressor pump. After about 4-6 pieces on a nested sheet the compressor has problems keeping above 90 PSI. The pump is just plain old tired, It’s about 25 years old with a TON of hours. 5HP single stage Campbell Hosfield unit. I can put a new 2 stage pump on it for less than $300. It will be nice to be able to hit start and walk away.

I checked with the “boss” re posting some pictures. As suspected she wasn’t too keen on the idea. It’s her IP so it’s her call…

Some additional info for this whole thing.

I talked to Hypertherm technical support, very helpful BTW.

Finecut consumables are a bit more delicate than the standard ones.

Their recommendation was:

Fine Cut Consumables

Shield 220948 Ohmic

Retaining Cap 222854

Nozzle 220930

Electrode 220842

Swirl Ring 220947

After around 600 or so pierces there is a noticeable drop off in cut quality. This also equates to about 30 min of torch time.

Hypertherm support said this is about all you can expect from fine cut consumables.

This is due to the close cut height and the resultant heat build up.

I suppose I could program in a pause between parts to let the torch cool down, that would help extend the consumable life. Definite option if your not in a hurry.

I did get another compressor head, just need to get it installed and plumbed up.

Too many projects!