I got my Crossfire Pro December of 2022.

I have read and learned valuable information from this forum.

I thought maybe I could “give back” a little.

I have read much about squaring the X to the Y axis.

Many actually disassemble their table to achieve this!

It stumps me why Langmuir does not incorporate an adjustable gantry to achieve this.

Some kind of a “Camming” system to allow perhaps up to 0.25in. of adjustment would be HUGELY beneficial to many users.

To expect everyone to perfectly assembly their tables is asking a lot.

In fact NOBODY can PERFECTLY end up and KEEP a square assembled table!

At least not to my standards.

Now if you are making signs, perhaps it’s not as important but if you are making “machine fitting parts” it is VERY important. I hold tight tolerances when I make parts. Even a “plasma” can reliably be plus or minus 0.005”.

This is what “I” did, it seemed to work very well and is quite simple.

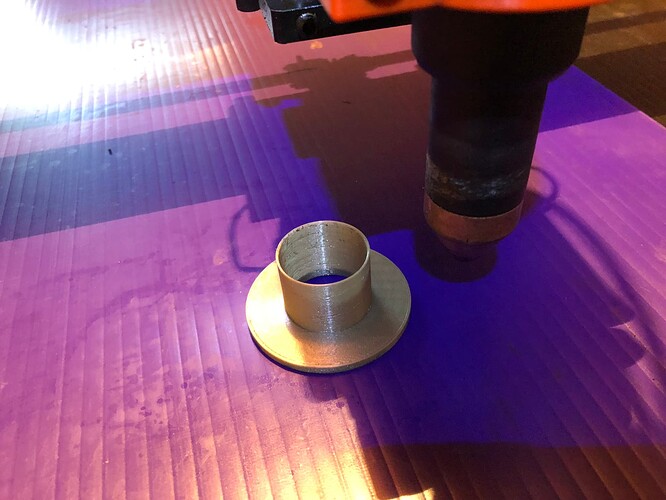

I simply turned down the 4 mounting bolts to provide a “recess” for the movement to adjust for miss-alignment.

It allowed me to adjust out 0.125” easily (I was OUT by 0.100”). Perhaps with “existing hole clearance” you can get more adjustment.

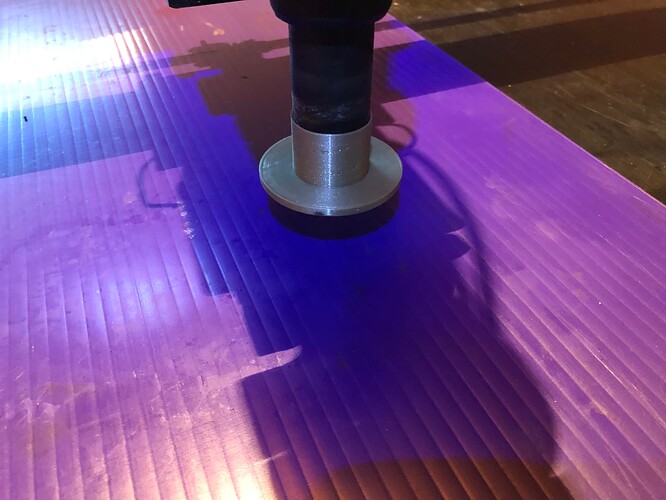

Also, I printed and use the 2” disc to run along a square and straight edge to do the alignment.

Made it very easy. Again, worked well for me.

I removed a “grooved area” about 0.300” wide “up” a little over 0.75” from the end of the bolt

You can measure your hardware and decide what you need to do.

I am sure with a sharp narrow grinding stone you could manually do this (a little craftsmanship!)

Anyhow, I turned the bolt down to 0.25”. That still leaves the same OD as a 5/16 bolt would have.

The full 0.375 bolt is really over kill for what holder/clamping pressures are needed.

You perhaps could get by just using a ¼” bolt replacement. If you used a Grade 8 ¼-20 it should still provide enough holder pressure. I did not test this as I “have” a lathe and elected to turn down the existing hardware.

Anyhow, hope this helps somebody else.!