I hope this topic will provide support for those setting up a new Crossfire Pro or similar setup who might have similar issues as I’m facing. I’m posting this here because none of these issues were user error but rather manufacturing/instructional issues that maybe someone else will face.

The first issue I faced with the initial run after assembly was the gantry kept binding. I adjusted pillow blocks and check square and alignment. Nothing helped. I noticed one of the screws getting a little warm. I double checked the build instructions and saw nothing about greasing the screws. Maybe some think this is standard or already know to do this but I did not. I thought they would need grease but the instruction manual didn’t say to and I thought maybe these were made to run greaseless. Wrong. I used a lithium grease and lubed up the screw rods. Problem solved. No heating or binding.

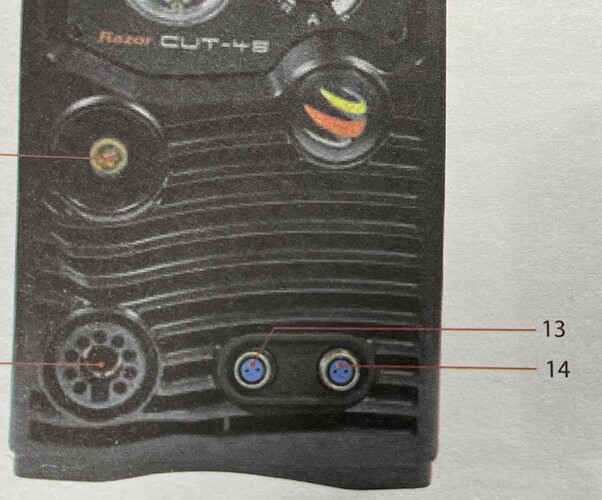

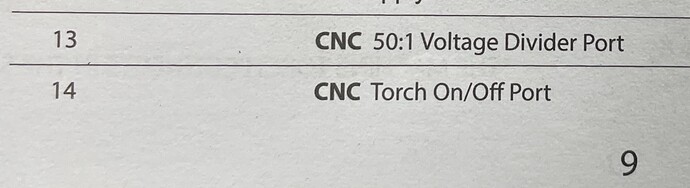

The second issue I faced was the Torch wouldn’t fire. I ordered the “plug-n-play” Razorweld/RazorCUT 45 so as to eliminate startup issues figuring I could upgrade to a Hypertherm down the road after some production. I’m happy so far with the machine as far as cutting goes. I’m cutting through 1/2 inch just fine (40A@10ipm,3sec pierce delay). The problem was… the manual shows the Firing port and the DIV Output are one way and they were actually installed backwards. I lost a few hours trying to figure out why it wouldn’t fire. Thought it was a number of things before I broke open the Razorweld machine and traced wires. Found them installed backwards. Major failure on Razorweld’s part. Bad QC.

Here’s what the manual says:

Here’s how it was wired: (You can see the red wire from the RIGHT plug is going to the red wire of the clamp.)

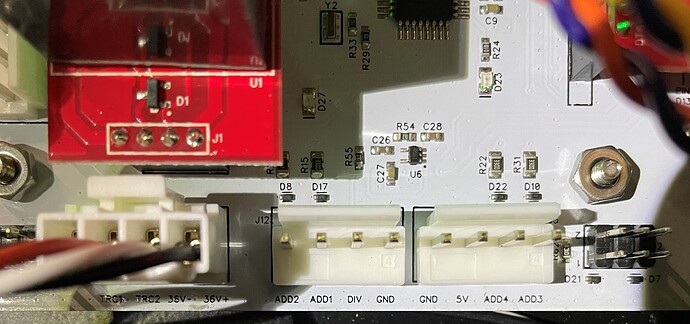

The third issue I faced was the THC (Torch Height Control) was not working. I followed the troubleshooting page (LS-THC User Guide | Langmuir Systems) and the troubleshooting flow-chart (http://assets.langmuirsystems.com/file/THC+TROUBLESHOOTING+FLOW+CHART.pdf) but neither really helped. I ended up going off-script and just began tracing circuits (I’m a EE and very familiar with circuits). I found the plug going from the port on the Control Box to the main board was plugged into the wrong port. From the FACTORY! When I was testing, I noticed a lack of continuity between the grey/white wires and A1/Gnd on the THC module. Upon further inspection and unplugging, I saw the labels on the pins (not easily visible when all plugged in. I moved the plug over to the correct port and Viola, everything worked just fine.

Here’s the way I found it as set up from the factory:

Here’s the labels:

Here’s how it should be plugged in:

My frustration is that none of these issues were due to my installation or operation or even environmental. They were all due to poor instructions or QC. I expected better. I’m assuming they’re not even bench testing these units. Just assembling and shipping. I think the steppers and boards and assembled units should be at least bench checked for QC. ![]()