So I have been toying with the idea of getting into making custom gates. We are mainly an auto fabrication shop building race cars and parts but am thinking of expanding into other fields. I figured if you have a CNC table, you might as well make the most use possible from it. Watching some videos, it doesn’t seem to bad to make them, and just from doing a rough calculation, it seems like profit seems like it would be pretty good. Is anyone else on here doing it as a business or side hustle? Good, bad, tips?

I have a very large project waiting in the wings from my daughter’s in-laws business. I just don’t have the confidence with my skills yet to follow through.

Here are some of the details we have discussed:

- The gate is 40 feet wide (20 feet swing to both sides)

- They would like a scene on the gate that looks as good closed as when it is opened.

- Since the scene would need to be a minimum of 4 feet tall and probably closer to 5 feet tall, we decided that it would need to be made out of 14 gauge or maybe 12 gauge material.

My concerns:

- Supposedly, the gate posts are designed to handle the weight, this would need to be verified

- Lots of indexing whether you had the Pro or the XR table (I have the Pro).

- Should we consider aluminum, or what type of finish - perhaps rust

- Due to all of the indexing that would be required on the Pro table, I would probably only design it and recommend they take the design to someone with a larger table.

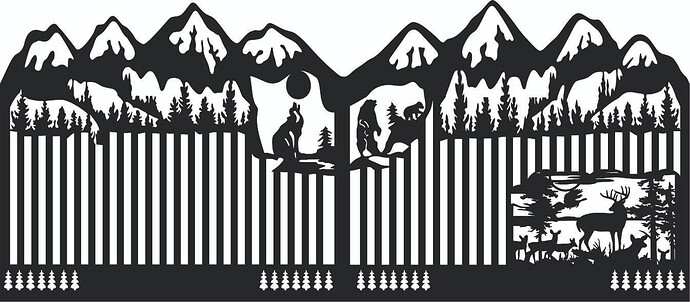

All-in-all, I love the idea. Here are a few plans that I purchased but have not done anything with them:

Food for thought in a design like the first one it may not look to bad to break it up in cuttable sections with a small border around it. Think stained glass. From a distance the ones that would notice will never be happy. I have seen wall art of trees done that way it is different but nice.

Wow!!! That is really cool man. Another thing I have read and watched is come builders are using thicker steel on the hinge side of the gate to carry more load then the rest of the gate

Agreed. But you also need to consider how the panels attach and how the supporting structure of the gate will add or detract from the design.

The part that consistently stops me in my “thought-track” is: If I see a design I like, I then consider how it looks from the backside. These people have the funds to do whatever with the signage so they are not as concerned with the cost as they are with the looks. I would guess the current gate cost them more than $15,000. Each post has about 7 yards of concrete. They put the gate in after they had a break-in so they definitely wanted to discourage anyone from thinking of breaking through. Now they want to soften the looks, so to speak. I believe it is made of mostly 3 or 4 inch diameter steel pipe.

No doubt that is a big under taking for sure. I like things like that with some kind of contrasting back ground that would hide stuff. If you ever Decide to try maybe do a scaled down version to see how it looks.

This photo (off Google Maps) does not do this justice but you can get a bit of a sense of a very unique gate design. This is only one half of the gate but when it is closed, it gives the impression you are looking at a steam engine. (I have taken pictures of this gate in the closed position but I am unable to locate it now.)