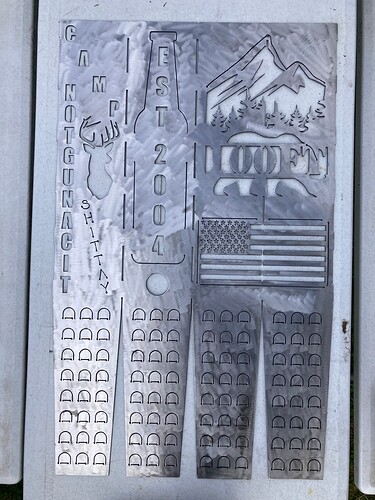

So now that I have about a month of using the CrossFire and I’m an expert (sarcasm) I figured I’d try my hand at a smudge pot, go big or go home. I’ll document it here in case anyone else was trying to make one as well. I started with Dillon J. Hart’s smudge pot design on Fireshare and tweeked a bit. Mostly the customization, some vertical bend lines, and simplified the many “vents” on lower part of the chimney. They were made up of a ton of tiny lines that kept causing Fusion to crash when I was trying to move them around. The chimney took about 17 minutes to cut and came out great. I ran into one issue while cutting this. The ground needed to be moved mid-cut, but I waited too long to pause the machine and move it. The torch was on the final perimeter cut and would’ve contacted the ground on the way around. I was forced to pause it and remove the ground with the torch still on, this obviously caused the torch to shut off. After moving the ground, the torch would not re-fire, no matter what I tried, and the cut path finished leaving about the final 15-20" on the perimeter uncut. I do not know how to restart a specific cut path in FireControl or if it’s even possible, but I didn’t panic. I moved the torch back to work zero, went into Fusion and made a new program with only the portion that didn’t cut, making sure to use the same box point reference as the first program. I loaded the new program, ran a test and then cut it, perfect! So far this is what I have cut. I need a bigger piece of metal for the base so I might not finish this right now.

First piece of advice from the Hitchhiker’s Guide to the Galaxy! Good job! ![]()

![]()

haha, I knew there had to be a fix. It might not have been the easiest one but was easier than finishing it up with a grinding wheel

@TomWS , Wasn’t that The Hitchhiker’s Guide to the Galaxy.

@mechanic416 - Depends on if he had is towel.

@rbs12 Welcome to the forum. Friendly suggestion, paragraphs are your friend.

I will try to explain without pics. I lose cuts a lot. THC, Overly sensitive plasma cutter detects low voltage and shuts off (air compressor kicks on)… Three things

One - Pause the cut only when it is in rapid to the next pierce. Firecontrol will not insert a torch start because you hit pause.

Two - Stop not pause the cut program at a sharpish corners or inconsistent radius (CAM will treat a consistent radius like a circle or arc as one cut, but any variances like a G will make several cut lines in it). Long straightaways are not a good spot to stop in, unless it is the first few inches.

Now in Firecontrol, in the machine window that shows your cut progress or the cut pattern, you can click on the line you want to cut / recut (might have to hit the X or Y move buttons to move the torch and see the line), and below the visualizer window you will see “Run from LOOP LINE”. Click on the LINE then click Generate in the popup.

You will now have a new cut program that will start from the beginning of that line you just clicked.

Three - Picking up where it left off, see above. If it is in a long straightaway, you can recut the whole line but it will widen the kerf not in your favor. Ramp the speed up to max and be ready to hit the reset button in Firecontrol to set the speed back to 100% when you get to the point it needs to cut normal again.

If your plasma keeps flaming out doing a recut, take a piece of scrap 20ga (thin is what we are looking for) and lay it over the line with the edge at the point where you want to pick up your cut again, let it cut at normal program speed if trying this.

In a pinch you can also ground on the slats rather than the media. Some of us, that is the only way they roll. Others have two grounds so they can move around. I keep one of those magnet grounds and a 12" x 1" Atomotive braided ground strap handy where I can clamp my work clamp to the slats with the braided strap in the jaws, and use the magnet to put on the work so I can move it with little fear of losing the connection.

Busted! Good catch, George!

AND, with my Superpowers, I have gone back in time and corrected that error, rendering this post and yours broken branches in time! Bwa Ha HA HA!

@TomWS ,Trillian said you shouldn’t mess with the Improbability Drive and change things. ![]()

![]()

![]()

Bah! What does she know? Arm Candy, if you ask me… ZAP! ![]()

![]()

Good for you: For coming up with a reasonable work-around.

@Sticks Nice summary of suggestions. I really like the idea of having two work clamp contact points for something like this.

Did you end up finishing this project? Curious how it came out and how it burns!

In the meantime while you’re waiting for the op of this topic to answer.

Another member @nicaDd had some success making his.