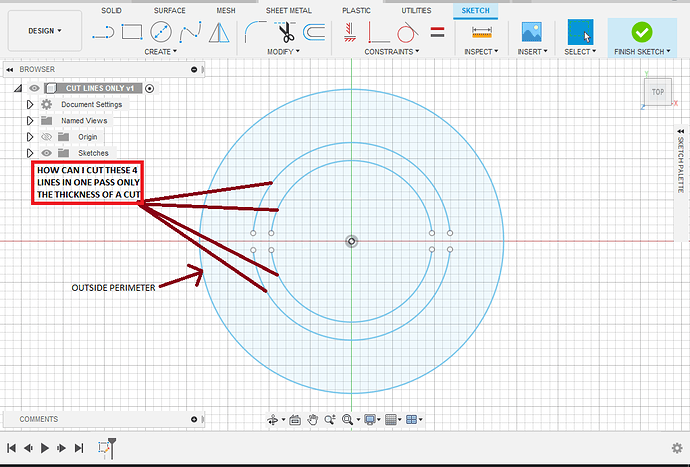

Trying to figure out how to make a single pass cut in Fusion360.

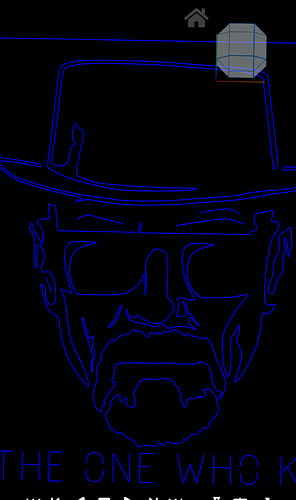

Every time I extrude in the pic attached it will not extrude the lines only the outside perimeter… Any advice? see attached

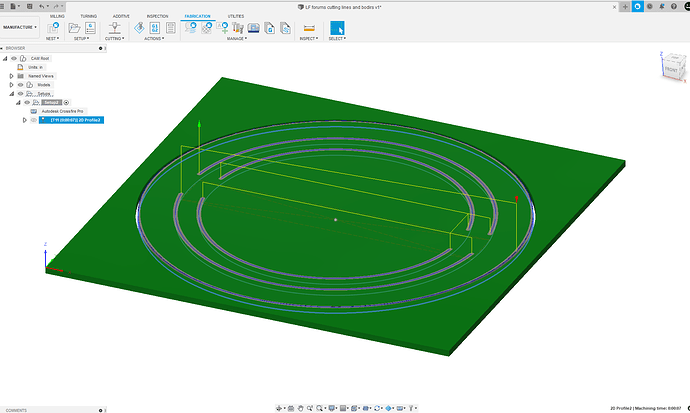

You will have to make sure your sketch is visible in the design workspace.

Then when you move into the manufacturing workspace the sketch will be visible.

Now in your 2D profile menu you should be able to select this geometry.

I would normally use a body for the outer cut geometry and all the inner cuts I would use the sketch geometry to create tool paths.

I have a video on here of doing exactly that I’m not at my computer right now or I would link it but if you search “loom” in the magnifying glass up above there was a video where I was helping someone with a telephone image that had some single line cutting involved but also a body.

The reason for this is extrusion takes a two-dimensional profile and makes it a three-dimensional body where a line is one dimensional piece of geometry and extruding it would only make it a two-dimensional surface.

There is a type of extrude that will “extrude” a line but with this type of extrusion does not become a three-dimensional body it becomes a two-dimensional surface.

LF forums cutting lines and bodies v1.f3d (115.2 KB)

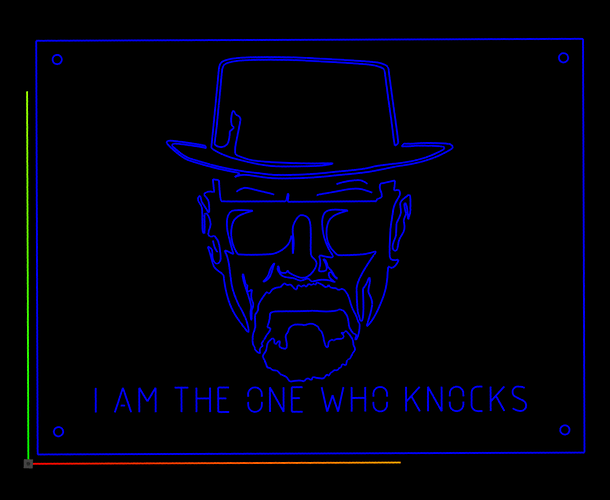

Here is it done using both bodies and sketch geometry to create one operation or pass.

I have attached a F3D file of this scenario

The only caveat is that your will have to add a kerf width to the outer diameter so the dimension remains true.

@TinWhisperer I got that drawing to work, unfortunately that is just something I drew up to get an idea how it works. The drawing I am actually working on is not cooperating for me and I can’t figure out why… followed your video in the other post the same way I did the one above… don’t get it tried multiple time with no luck… Here is the one I am working on attached

BBSIGN v1.f3d (222.0 KB)

I’m out in the field for a few hours but I’ll take a look at it when I get back to my office.

What parameters are you running for your torch and case I get to developing some CAM.

Inches per minute.

Cut height

Pierce height

Kerf width

Extruded .125 mild Steel

I use 0 side and top offset

Everything under feed at 50 inches per minute

Select always inside

Tolerance .0004

Sideways comp left

Compensation type in computer

Finishing overlap 0

Outer corner mode roll around corners

Preserve order yes

Talked to leave zero

Smoothing zero

Feed optimization zero

Nozzle down yes stay down distance 24 in

Cut stock clearance .015

Force retract for inside cut no

Stay down feed rate 50 in

Leading entry checked

lead in radius 0

Lead in sweep angle 90

Leading distance zero

Lead out exit no

Pierce clearance .015

If you need anything else send me a message. I’ll be home ain’t going nowhere got the covid figured I’d try to work on this while I feel like crap and stuck in the house. Thanks for the help. Really need to learn how to do this thing with the lines…

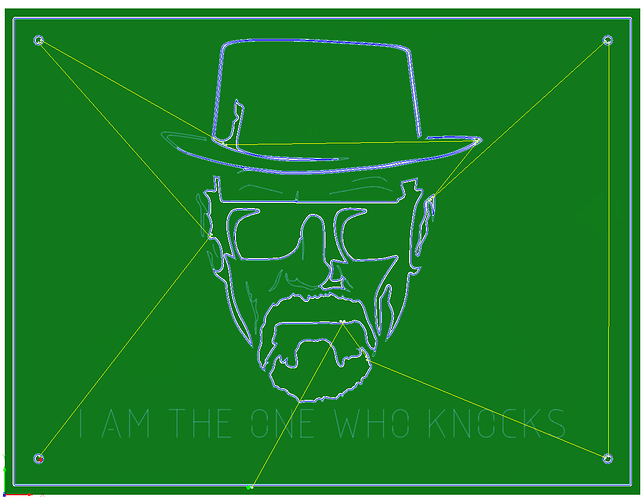

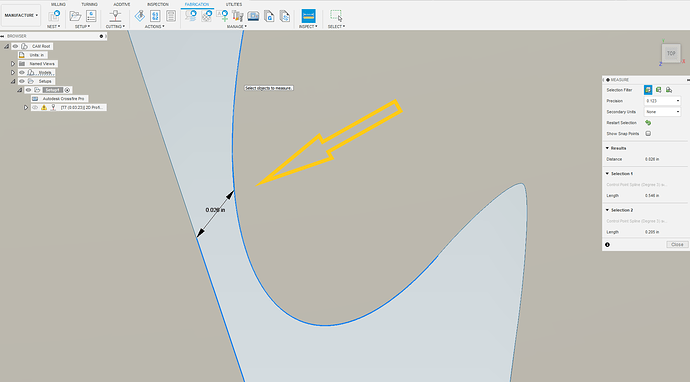

Some feature s are very small.

The whole plate is only 14 and 1/2 in across

Green image at .055 kerf

I can see why you were having issues.

at this scale you are not going very great representation of your image.

The kerf will likely be around .055 and there are areas where it half this or less.

You may have to adjust the size

I also had to do it in two operations there’s just too much complex geometry that needs to have cutting on one side and then if you try to line cut on top of that that needs to be cut on center it just becomes messy. Possible but messy.

here is a attempt with very reduced kerf width (.017)

IAMTHEONEWHOKNOCKS v2.f3d (847.2 KB)

IAMTHEONEWHOKNOCKS.dxf (211.6 KB)

Iamtheonewhoknocks.nc (205.1 KB)

(edit : switched operation order )

this cut file is at 50 ipm but with the incorrect kerf it likely will turn out odd.

I attached I DXF maybe someone can take a run at it with sheetCAM.

I hope you get better soon.

The line weight of the tool path doesn’t properly represent the kerf width of the tool in these shots.

But it is a complete tool path and it will attempt to cut that geometry at 14 and 1/2 in.

Thank you again, I will hopefully get some time to work on it this weekend. I know it’s tight but I have cut things like this before with success. I got the tool path to generate on the face, just could not get it to allow me to do the thin lines and lettering. Hopefully this will work for me much appreciated obviously a guru you are…

Thanks again!