ok I will keep working on it thank you

So I have checked all bearing and lead screws, everything is tight and there is not any play. Would bad consumables or the thc doing a sewing machine maneuver cause this bad cut quality? also my nozzle seems to wear when I look at it from the inside but looking from the inside it is still circular. Would the nozzle cause this? or wet air? I cant find anything that is loose on the table.

I did have a nozzle issue that the wear was so consistent that it was not really visible to be an issue. Changed it and it resolved all the bevel I was having. So you should definitely change the nozzle and try a new electrode. If that doesn’t change things at all, go back to the old consumables. No sense wasting new consumable life as I think it is a different issue. This is not consumables unless something is loose or broken with the torch stack. Something shifted:

Check all the consumable stack. Look for a chip or crack.

The sewing machine action: It is hunting for the right voltage. Try to set up a cut with only IHS and without THC: That would remove “hunting”. Try just a simple square/rectangle. Try this at different spots on the table to see if there is a spot that is “hanging up” on the lead screws.

If that removes the issue, perhaps there is something up with the THC module. That is a call for Langmuir to help you diagnose. But if you go that route, they will want you to go thru this:

THC+TROUBLESHOOTING+FLOW+CHART.pdf (6.3 MB)

ok I will do this after work. thank you

Grab the torch and try to wiggle it back and forth. If there is any movement other than up and down, that needs to be fixed.

Is there a chance the torch slapped the material and moved it?

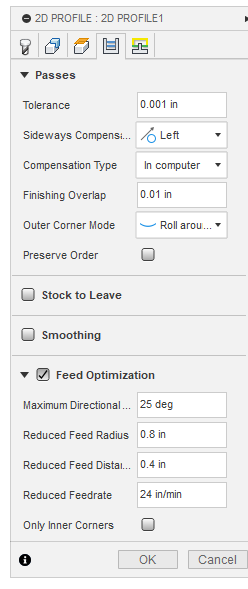

This was cut using fusion, it looks perfect to me. this how they came off the table. I do not know what happened the other day. Maybe tightening the bearings worked. I also used my old consumables. This is another question but since im using the free version of fusion i cannot save a dxf for sheetcam and have to use the fusion cam. Is there a way to reduce feed rate for holes in fusion? I have a slight bevel on the .5" and 1" holes.

Thank you!