All,

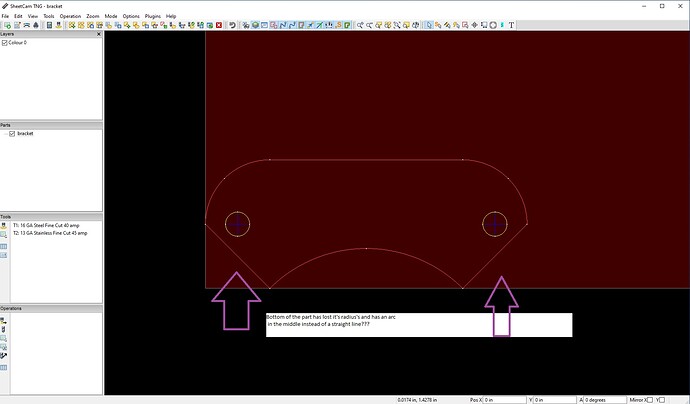

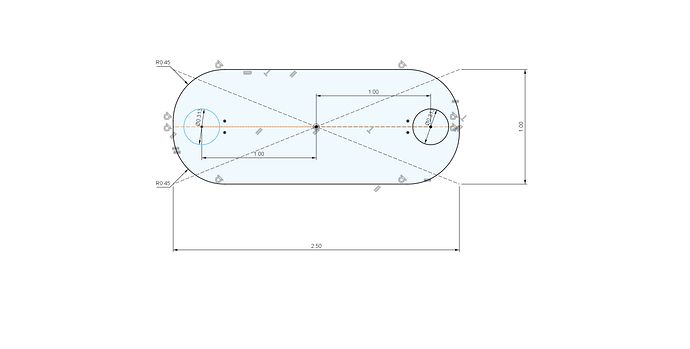

I am importing a very simple part from F360 Into sheetcam but when the part opens in sheetcam it looks nothing like the part i designed. Specifically the bottom half of the part has changed drastically. I have uploaded screenshots from each program to make it more clear on what is happening. If anyone could take a look and give me some suggestions I would appreciate it. The problem specifically happens when i add the radiused corners. If i design the part in f360 to be rectangular without radiused corners it inputs perfectly.

Some kind of tolerance issue?

Try switching those corner radii to .45 then try again.

Or recreate it as an obround (two half circles with a rectangle in between) instead of fileting the rectangle.

Does seem suspiciously like a tolerance setting.

Or the two lower corners aren’t connected to the line and it’s drawing an arc to connect them.

small fusion part lf.dxf (3.6 KB)

I used smaller radii .45 instead of .5 I am sure if you changed it to .499 it would work too.

TinWhisperer,

So i took your advice and created a new part but this time i did use two half circles instead of using the fillet tool to radius the corners. That said it imported perfectly into sheetcam with the two half circle method. I haven’t tried manipulating the radius’s on the original part yet but i will definitely do that next. Thanks for the quick advice!

I did originally draw this by starting with a rectangle and then using the fillet tool to radius the corners so i assumed that the lower corners were connected. That said i am wondering if having the fillets so closely together caused the glitch?? Anyway thank you as well for jumping in here and helping me out! Much appreciated

TinWhisperer, i am going to change the original part now and try out the .499 theory. All good stuff here. I sure am glad there are great folks out there like you that are willing to jump in and help out us newbies

I have very little experience with sheetcam myself.

I have the limited version I should just bite the bullet and buy the full version and learn it.

Why not use fusion 360s CAM on this part?

Is there some features in sheetcam that fusion 360 doesn’t have or that work better than fusion 360s features?

I haven’t been able to find fusion 360s plunge feed rate from pierce height yet so that’s one thing sheetcam has on fusion360.

I’m really curious cuz I see quite a few people using the cad environments of fusion 360 but the cam environment in sheetcam.

You are very welcome.

Well… the reason i am using sheetcam is actually from not having experience with the plasma cutting world. When i purchased my machine i just assumed i needed to get sheetcam as well. A few other friends of mine that have plasma tables all use sheetcam and i honestly thought that it was just the go to program. I had no idea that F360 also does CAM! That said i will learn cam in F360 as well so that i can compare the two. If i had known that F360 did it all I probably wouldn’t have purchased it. So… since i purchased sheetcam i figured i need to learn and use it. I am very interested to learn cam in f360 and compare them. I am a mac guy so it would be much easier for me to do it all on my mac instead of using a pc just for sheetcam. Live and Learn!!!

Thanks again for all of the suggestions and help.

-Jordan

Jordan,

Did you get my email asking for a copy of the problem dxf file? It does look like an issue in SheetCam and I’d like a copy of the file so I can try to figure out what is going on.

Les, I sent you the file via email. Did you receive it?

-Jordan