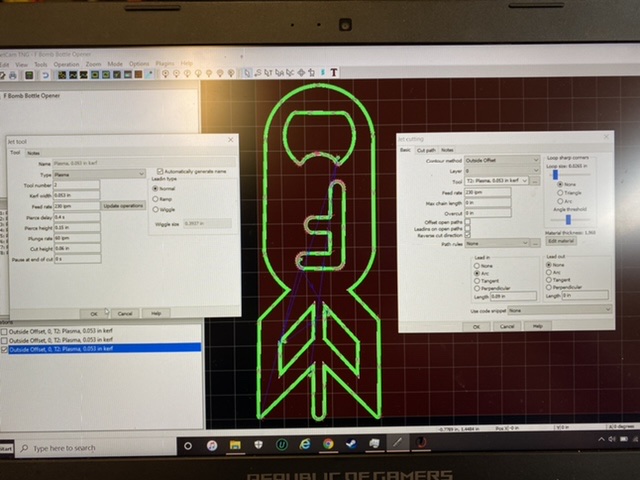

Could this be my torch height control? I cut another smaller piece right before this one just fine.

Any help is appreciated. Thanks.

pug address sign for Bri - 7-10-20.tap (18.2 KB)

Could this be my torch height control? I cut another smaller piece right before this one just fine.

Any help is appreciated. Thanks.

pug address sign for Bri - 7-10-20.tap (18.2 KB)

Looks like pierce delay, torch actually firing a fraction of a second after the relay closes and torch moves too soon. Double Pierce delay and you’ll be fine.

Maybe your smaller piece had a different or longer lead in or only one pierce? I didn’t notice my pierce delay issue on my first few test cuts because they were just solid objects.

It is my pierce delay. I watched a video I made of me cutting that peice and u are spot on. I will try a little more on the delay.

I think my smaller peice had a .2 and the one I am having issues with in pic was .1.

Do u think I should apply rules in sheetcam to slow it down on the tight corners?

I’ve been cutting all 16g mild steel so far at 30 amps and 215-230 IPM. I have experimented with the holes and corners rules on inside contours. I wouldn’t apply them for the outer paths. I’m not sure I’ve seen a difference yet.

I have been using loop sharp corners though.

The only tight corners on that are your numbers and they look fine aside from the pierce issue.

So I got it working pretty good. Factory recommendations were followed except I changed cut speed to 230IPM, 35 amps, .4 second pierce delay. Attached are pictures of results with these settings. I might try doing 30 amps like you initially recommended and see if it improves. I still have some minor flaws I can probably improve. Picture with failed cuts is using .2 second delay at 230 IPM 35 amps. .

Yeah, the HT’s manual has delay specs that are too short for the way our tables work. The HT has a circuit that tells when the arc is established and that’s when their pierce delay timer starts. Our table starts the timer when the fire command is triggered. The delay between telling the torch to fire and when it actually fires results in too short a pierce delay if you use the manual’s recommended settings.

Has anyone came up with a revised chart on pierce delays for the various gauges of metal, consumables and types of metals for HP 45XP? That would be awesome and save me some experimenting. I plan on cutting 14 gauge and larger metal soon.