So I read the SheetCam manual, followed their instructions and set myself up to run a drilling operation using points set in a drawing. I have the drill points on one layer and the part outline on a different layer. Set everything up per their instructions and things look good. Go to run the cut simulation and it gives me an error message stating that there is zero feed rate and no motion is possible. Pretty frustrating as I really need to use this feature for accurate hole placement for automotive parts. I did read somewhere that it my be a license thing? I am using Solid Edge 2020 for design and SheetCam (free version) for post processing. I have cut several projects with no issues. I just can’t use the drill operation.

Sheet cam free limits you to a certain number of lines of code. From what I’ve read it’s easy to exceed. I’d be willing to bet that’s your problem.

I haven’t messed with the drill function on sheetcam, everything I’ve done has been just drawing the holes in my .svg files and having sheetcam cut them as is. Haven’t had any real issues, but I’m not exactly building to aerospace tolerances.

SheetCam Demo version is only useful enough to show you how easy it is to use. It’s not useful enough to cut anything meaningful.

Re Drill operation, you need to define a new tool that has the operating parameters. Also, you don’t drill ‘points’, you drill the center of holes. So, if you have a 0.125 hole in your design and use the Drill operation, SheetCam will ‘drill’ a spot in the center of the hole.

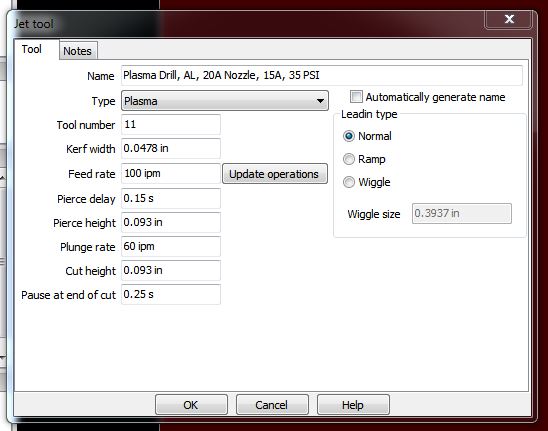

Here is the Drill tool I use with SheetCam:

Thank you guys. I went and paid the $150 last night for a brand new license. Installed it, and that did not solve the problem.

TomWs, I completely understand what you are saying. Question, do you leave the holes drawn in a layer on the project? I.E. - part Outline on one layer, holes on a second layer, and points for the holes in a third layer? And then perform a drill operation on the points layer and a cut operation on the Outline layer?

Also, I do not have the THC so do I just zero out those values? Will that effect this operation?

You don’t need the points or points layer. You just want a holes layer and a cut layer. The holes layer is for the holes in your design. Those holes should be spec’ed the size you ultimately will need. The drill operation is going to “peck” at the center of the hole to try to pierce & "drill’. You won’t get a hole because you really don’t have a drill but you’ll get a divot.

You’re faking it out. The machine thinks there’s a drill bit in your CNC the size of your holes. So it “drills” and then moves on.

Presumably you don’t have Z either and that’s what matters. Since you don’t have Z, your pierce height is the same as your cut height, I would experiment with a bit shorter pierce delay so you don’t burn through the metal - the goal is to just blast it with an arc to pit the metal at the center of the hole.

So progress. SheetCam runs the cut and drill operations in simulation just fine. I post process and load the .tap file into FireControl for my Crosscut table. Everything functions the way that it is supposed to with the exception of one thing… the plasma cutter does not fire to drill the hole. The head moves and stops at each location like it is supposed to but it’s not firing to pierce. I do not have a height controller so my pierce height and cut height are both 0. Plunge rate is 60ipm. I am using points to pierce not holes.