ok how do I narrow the kerf/cut of my torch in sheet cam it is cutting 3/16 now would like it 1/16 or less is that possible and what is the best cutting height

Sheetcam does not change your kerf…your kerf is made depending on the size of your consumable nozzel and the amps and air…

All Sheetcam does when you input a kerf size is show you a wider kerf in the drawing when you go to post process…

(the following are exaggerated examples…not actual kerf widths)

below are 2 pictures…one has a kerf in sheetcam at 0.025

This one has the kerf in sheetcam at 0.01

All this does is show you how tight the detail cutting will be IF and only IF your actual kerf is cutting 0.01

so what you need to do is to measure the kerf you are cutting now…then change to a fine cut consumable and measure that kerf…the measurement is what you enter into Sheetcam…

AGIAIN…sheetcam does not adjust the actual cutting flame on the plasma…it is only a number you input based on actual measurements you make of your cut.

does that make sense?

cut height is usually best at 0.06…but again…that is measurement you to adjust in sheetcam…

so set it at 0.06…start the cut and then pause the cut…measure the height…if it measures 0.08 then it is too high and you need to change the setting to 0.04 in sheetcam to offset the difference.

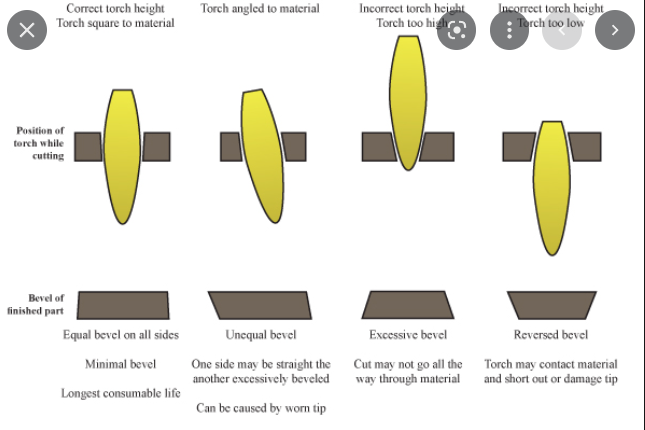

here is a good example of what happens when the torch height is not set properly.

For each tool in the SheetCam toolset, there is a Kerf setting. That setting should reflect how much kerf that tool takes when it cuts. Generally it would be between 0.045 to 0.060 inches, probably around 0.052, but, as @toolboy tried to say (hehehe), you need to determine your kerf value by using test cases.

I don’t have SheetCam handy on this system so I can’t do a screen cap.

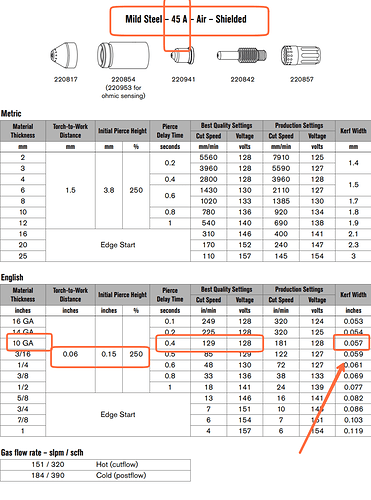

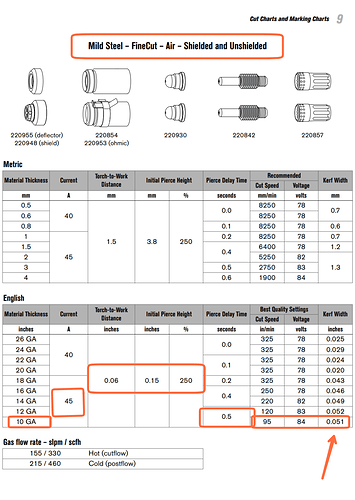

were would I find fine cut consumable and what should I be looking for my plasma is a Hypertherm 45xp. cutting 1/8"

The way I read the question he was wondering where in sheetcam you can input your kerf width?

I guess I was wrong.

Probably 0.045-0.047 would be my SWAG on that.

@mechanic416 is a member here…he has a plasma shop online

There is no way that your hypertherm 45xp is cutting a 3/16 kerf. That is in the oxy/acetylene torch cutting range.

As stated above your 45xp should be cutting a kerf between .040" and. 060" with standard consumables.

My Everlast with a .9 nozzle cuts an .043" kerf with a new nozzle.