Need some help when setting my cut feed rate in sheet cam I have it as 90IPM and then on my longer runs i have it set to 100 but when I cut its not changing speed. Is there a setting I am missing to get my plasma cutter to read my sheet cam speed. I am running the Crossfire XR

How are you setting it to a different speed for “longer runs”?

A path rule is the only thing that comes to mind for something like that.

Be careful with setting some sections at a higher speed than the main program speed. If it is more than 15% higher than the main program speed, it will shut off the THC.

What happens is that Sheetcam uses the fastest travel speeds in the program for the program speed that the THC uses. Any time the speed drops below 85% of that speed, the THC will turn off.

I have been working on custom signs with thin metal. I have found out that when i set my machine to 100IPM it has been cutting better but i want it to slow down just a little for like straight cuts, so it burns the edges just a little more and not have the hole for the pierce and then a thin line. if that makes since.

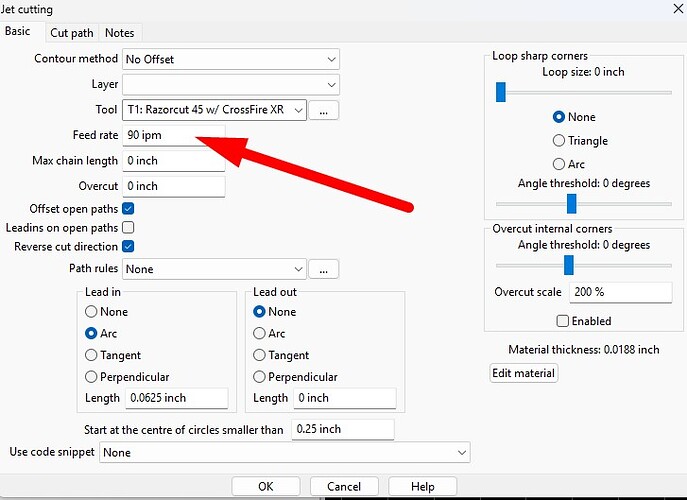

I have been adjusting the IPM in the sheet cam program that you can tell it what to set but i cant get it to work.

It doesn’t work like that. I’m not even sure there is a path rule for straight cuts. Most people want to slow down for curves and holes.

Whatever tool you use to create the operation is the speed it will use, unless there is a path rule that tells it to slow down a certain percentage for features like curves and holes.

If you’re taking about open paths, like bend relief lines, you could move them to a different layer and create a different operation for those, using a different tool.

You can have multiple operations in one G code file.