Hi. I’m new to Sheet Cam. I made some designs, but when I try to cut them on my Crossfire XR, the torch moves very slowly. Has anyone else had this problem?

You have a program speed of 3 I assume Ipm . What are you cutting and what do you have the speed set for the tool you setup?

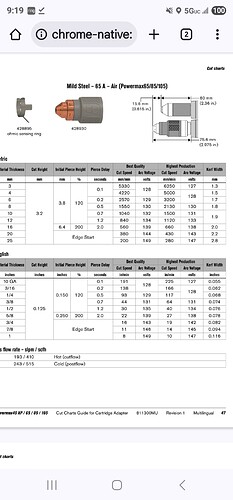

It’s for 3/16" material. I configured it in the sheet cam following the Hypertherm 65A specifications. But it seems the speed isn’t correct and I’m not sure what parameter I should change.

Do you have a cut chart? You go to the tools set select the tool you have for 3/16. Change the cut speed. Off the top of my head you should be 120 to 150.

According to the Hypertherm 65A table, the speed cut is 138 in/min. but my torch still moves very slowly.

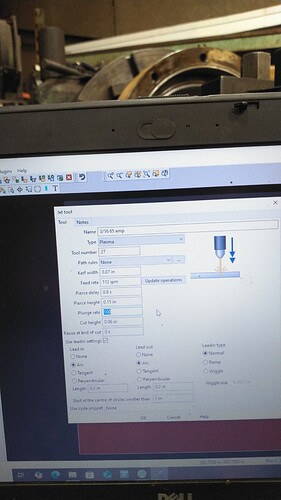

You have to change it in your sheetcam settings. I will post a picture of my toolset. Arclight has great YouTube tutorials on sheetcam. I recommend watching them.

Here is my 65 amp 3/16 tool. Keep in mind hypertherm recommends a slowdown of 20 percent using a water pan. That is for non sync which I have. You will need to adjust the plunge rate as well if you haven’t done that too.

Had to do a picture I don’t have Internet service to do s screenshot.

Thank you so much for taking the time to answer my questions. I think that’s my problem. My plunge rate is 3.4 or something like that, but I wasn’t sure what its function was. Thanks.

Do you have a toolset for cutting 14ga material with fine cut consumables?

You are welcome. Plunge rate is the rate the torch moves from pierce to cut height.

I do not have a tool for fine cut. Hypertherm is spot on with their charts. The only exception I can’t say about the sync models I slow down 20 percent because of the water pan. They made the cut charts using a downdraft table.

Any parameter may need adjusted to fit your setup. A lot of folks also have to tweak their cut height settings to get the actual cut height needed. Don’t want to throw to much at you at once. That is something to look at when you need to address a cut quality issue.