Does enyone have a toolset for Sheet Cam using an Everlast 60 cutter? Thanks in advance.

Looking for the same. I have the Crossfire and Everlast PowerPlasma 60s.

I think reviewing some video on YouTube will help you. The info you need will be there after looking at a few.

Some if the big table manufacturers use sheetcam and produce some great videos with excellent info.

The videos by small single table owners are not the ones to watch in the beginning.

If you are looking for specific speed numbers for your plasma cutter do a straight line test.

That info has been listed here many times. Hope that helps.

Sheetcam is the best!

I’ve watched several of the “commercial videos “ and they have been very helpful. In most of them they have a toolset for Hypertherm. I was just hoping someone had done one for the Everlast 50/60. And yes so far I really like Sheet cam. I’ve been using Fusion and on most things I have tried cutting I’ve noticed that it slows the cutter down very slow on curves. The worst is when I import lettering from CorelDraw as a dfx file.

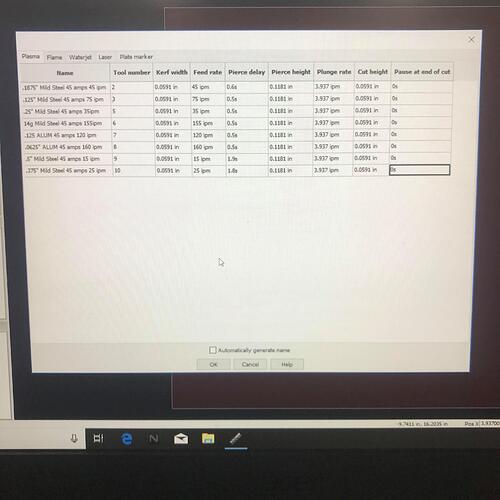

Thanks Dicky for the share!

We’re those settings web settings or ones you created with the actual 50s?

What was your air pressure? Saw another post with a wide range of psi.

Shared with me by another 50s user. They work. I run 70psi consistantly

that’s what i read as well, i was even planning on calling Everlast tech support to get their recommendation. would like to hear back from the guy running at all the different psi’s to see his acual cut results.

What tip were u using? Same kerf all the way down

I have the 60s and I’ve only cut about five items. I ran the 60amp and the 40amp tip at 75 psi and I liked the way it cut. I ran 130ipm on 16 gauge steel. Hardly any dross on the back. I ran two cuts at 40 amps and two cuts at 36 amps.

Still not sure completely what I’m doing, thus the wrong tips at the wrong amps.

Pierce delay was 1.1

I’ve been running 16g .06 @ 42 amps with a 1.0 tip 70 psi w water table and air cooler. Has been absolutely beautiful. However, it’s been iffy on some small stencil fonts. So I just got the .9 tip and am planning on giving that a go this weekend.

I use .9 tips on everything 14 and 16g

PipeandWire what IPM are you running at? Just want to compare it to what I’ve been doing.

jr

check your lead out - and also try smoothing in your setup.

if you are cutting clean, no problem but Id probably lower the amps to the 25 range for this and run my feed rate slower. I guess it depends on how much detail is your cut. Actually , id think your pierce delay is the bigger issue. i think with that much ampage on something so thin youd be melting out pretty badly. bring that down to something like 200 ms

i WAS running 42a at 150 w 1.0 50a tip. ive since changed to 28a @ 145ipm w a .9mm tip tip at 75psi .3 delay and .07 kerf .04 tangent lead in all on 16g steel. also using air dryer. extremely happy with all my cuts. i have some nice pics of my setup and some other little things ive done w the table, but its a touch faster then i would like but the combination allows me to get smaller letters without heating up and interfering w letters next to it.

i have 4 separate corner posts on 3/4 threaded rod to laser level the the table, have a rolling wheel on the far end of the gantry so the arm doesn’t bounce when fully extended, have an additional conduit mini supporting the top part of my torch and i use flat magnets to keep the media from shifting.

have couple more things to do and will post all my pics.