I’m a novice with my Crossfire pro, Everlast 82i, PTM-80. I’ve been using a cut chart I found on this forum to cut 1/8, 1/4 and some thinner stuff with no problems. Yesterday I tried to cut some 5/8 mild steel and it was a disaster. The chart calls for 60A at 18ipm using a 1mm tip. Since I haven’t had any cutting issues I was slow to realize that all the slag was blowing up onto the torch because it wasn’t cutting through the stock. At one point I got a good straight cut using 70A and a 1.2mm tip. The part I need has several 3/4" circles and even though the 70A worked for the straight line it was a globby slag mess on the circles. While I’m waiting for new torch parts I thought I would ask for advice. Is there a problem with cutting a series of 3/4" circles in 5/8" stock? what settings should I use?

Thanks!

60 or 70 amps, 1.5 sec pierce delay, 20 ipm will get you close. Two things: fill the table with water, and watch out for the duty cycle trip. 6 to 7 minutes or so per part. If you’re cutting holes, slow down the IPM to around 14 or 15 .

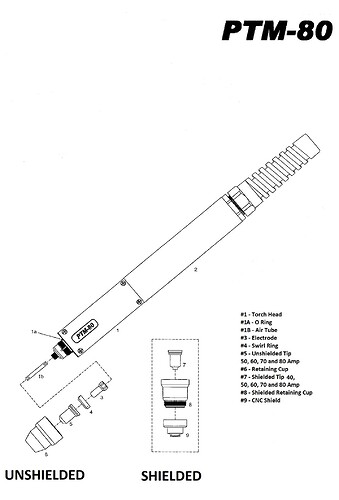

Until you get more experience with your table and plasma cutter I would just drill the 3/4" holes. A 1mm cutting tip is rated at 50 amps not 60 a 1.1mm is rated for 60 amps and a 1.2 is rated at 70 amps. Also your flow air pressure should be 70/75 psi for metal over 3/8". Post flow 30 to 45 seconds is best.

Thanks guys. I can do the holes as a pattern on the mill. This application isn’t critical on tolerance so I’d like to invest the time now and learn how to do it on the Crossfire. I’m also learning Fusion and I don’t know of a way to program different feed rates for different sections of the same part. Am I missing something?

When cutting holes in thick metal, the plasma stream tends to bevel, and also case hardened the hole’s perimeter. Cleaning up with a drill bit could be very, very difficult.

I think you are asking about Feed Optimization. Look at the bottom of the fourth tab when making your Tool Path. There is a box to check to edit and change the speed of the cut. Make sure to scroll down to see all the selections in that drop down.

I rarely use it so I hate to give too much advice, but reading this forum I see 50-60% cut rate of your program speed would be a good start point for your circles.

Feed optimization sure looks like what I was asking for - thanks!

Now on the topic of circles, I’m hearing that small circles in thick material are a bad idea. Please help me understand the limits here - if 3/4 diameter in 5/8 stock is too tight, can I cut those same circles in 1/2 or 3/8 stock? Is there some relationship of diameter to thickness that I can use as a rule of thumb?

My rule of thumb for this is usually as soon as the diameter is less than the material thickness results become less desirable.

Absolutely feed rate optimization helps this issue.

Hmmm…I wonder if I can go back and cut those 3/4" circles in 5/8" stock using 70A, 1.2mm tip, 75psi air, 18 in/min and have feed rate optimization drop to ummm…10?

I would try cutting a hole on a piece of scrap stock and see what it does.

It just so happens that i now have an 80lb plate of scrap ![]()

I learned this from experience. It is particularly bad when you have enough water in the table to splash up to the cut. The quick cooling makes the cut edges really hard. It makes drilling extremely bad on the drill bit. I have gone to making a mark on the surface of my plate then drilling appropriately.

I went to shielded consumables from George and will never go back. Night and day difference, especially with aluminum. Just my two cents.

100% what ^ said. Either drill it or plasma cut it. Trying to both is a disaster. ![]()

I ended up cutting the part in 3/8 using feed optimization which helped a lot. The straight lines cut nice using the chart settings, The holes were okay but not great. It looks to me like the torch isn’t staying at the pierce point long enough and creates a slag mount that follows the torch until the cut stabilizes. When doing multiple holes the slag can accumulate on the torch. I have the pierce delay set long enough for the torch to fire reliably but I can’t find any setting that allows the pierce itself to complete before the torch runs into the cut. What am I missing?

With Hypertherm typically you start increasing your Pierce height on thicker materials I’m assuming Everlast does the same.

THC does this?

I cut 3/8 A36 several times a week.

60 amps

.06 cut height

.12 pierce height

39 ipm

1.2 pierce delay

75 psi while cutting not 60, 75.

It works every time.

Use the chart I posted above.

Everlast 82i cut chart3.pdf (173.1 KB)

Perfect - thanks!