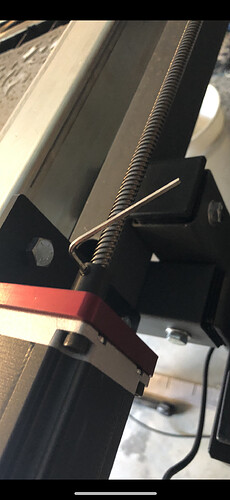

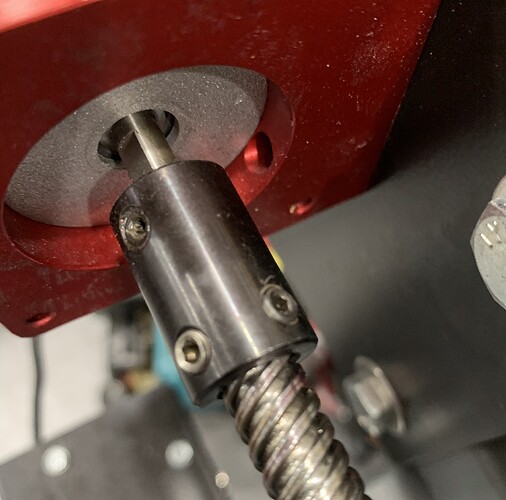

Issue with this screw coming loose mid project, keeps happening. Wanted to check with you guys. Thinking about drilling a “notch” in the rod for the screw to set into. Then locktighting it. Any advice before I mess it up lol

You can do that, but i’ve never seen the issue not resolved simply by tightening the set screw sufficiently. The set screw will create its own divot in the set screw which will prevent relative motion and prevent vibrating loose. Every machine we have assembled here has not had loctite, but theres nothing wrong with a dab of loctite on each screw.

I’ve been fighting this one for a few weeeks now. I’ve gotten it to where I tighten it for each project. But on longer projects i will start to notice that axis slipping. Stop the cut and check that screw and it’s loosened again. When I tighten it. I go about as tight as I would trust the head not to strip. (About 1/2” deflection on the Allen key)

Did you try adding a dab of oil on the screw then tightening? I’ve been running mine for 6+ months and they have never came loose on me

I had the same issue when I initially assembled the system; I found that the hole for the set screw was not sufficiently tapped all the way through to allow the screw to tighten on the shaft. I had to tap the threads all the way through the coupling and that resolved the issue.

I’ve definitely noticed this!! Even after adding loctite! I just tighten before every longer cut, or every few short ones. Would love to figure out a permanent solution. Fjfudpucker, I will check that for sure, maybe it’s the problem!

I had this same issue, mine would come loose and start slipping even on short cuts. I finally loosened both set screws and slid the coupler just slightly more towards the drive motor and I havent had a problem since. I could see the divot on the motor shaft where the set screw had been tightened but it was not holding.

I had the same problem after taking mine apart to check bearing preload I actually took the lead screw and used a center drill to leave a divot for the set screw. I also added another set screw at 90°. Since then have not had a problem with it coming loose.

Glad to see this is a real problem and I didn’t mess up something on the install! Going ahead with operation repair!!! Thanks for all the advice.

I have the exact same problem. I put red loctite on them and they still backed out. I only run a couple parts a week. Will have to try the center drill idea out.

You might have an angle grinder handy, grind a flat on the leadscrew. Done. Locktight also works, but a grub screw into a round hardened leadscrew? I’m a machinist’s worst nightmare, but even I know that’s not going to hold!