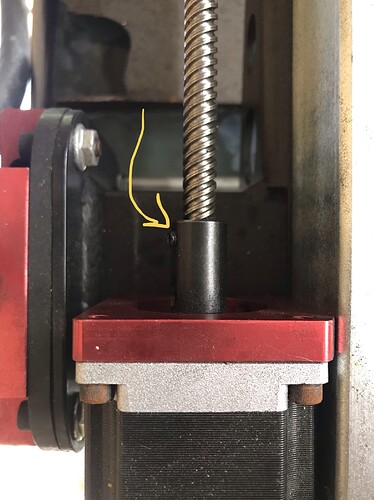

Can anyone recommend how to fix the issues in having with my table. The coupler attaching the motor to the x-axis lead screw fails after running the machine for about 2-3 minutes. It’s the set screw on the lead screw side. I’m having to tighten between cuts and feed hold on larger cuts. Should I use locktite?

I didn’t put the machine together and it worked for an hour or two of cuts before this problem showed up. I’m wondering if there is something that could’ve been missed. Thanks.

I wouldn’t be afraid of the blue loctite. But I have zero issues with mine. Maybe see if you can tell if it’s engaging the groove of the screw. Seems to me that’s where it should be. Idk. I had uses with the motor side… but that’s because it wasn’t on the flat.

Have no issue with mine. Been using quite awhile now.

When it was tightened it may have been stripped or cross threaded?

You may need a new coupler and set screw or if you have the tools you can drill it and retap it and install a new Allen head screw and loctite it.

If it won’t stay tight it’s most likely stripped.

I had the same problem, drove me nuts.

Turn the screw in until it just touches the lead screw lightly, turn the rod with slight pressure on the screw, you will feel the groove of the lead screw as the set screw rides the highs and then the groove, when your in the groove tighten the hell out of it, I added loc tite the last time. Never came loose again and came apart fine when I installed the xl kit.

Do you think you could drill small indentation with a drill bit to give the set screw something to bite into?

mine does it all the time on the Y axis farthest where the bearing is. it used to be the bigger allen screw would come loose on the bearing. Once I tightened the heck out of that, now these set screws come loose.

I ground flats on my leadscrew at assembly (both sides) then locktite on the setscrews(blue). Running a drill bit the same outer diameter as the set screw (or a hair smaller) to give you a point for the setscrew to seat in will work too. Just be sure to use an airgun to blow out the chips afterwards and wear proper eye protection while doing so. Also make sure you are lined up either on top of a thread, or between the leadscrew threads so your drill does not wander and tear apart your set screw hole… Mine has not loosed up since day one…

I had a similar problem with the set screw coming loose constantly on the y axis. So I ground a flat spot on the lead screw and that has mostly fixed the problem. I will probably put some Locktite Blue on the set screw if it happens again. My x axis has had no issues.