Looked and could not find an answer to a probably simple question. I use a late model Cut60 on a CfPro table, works great, adding thc once its delivered. Question: manual chart works fine, 32 amps for 14ga, is that what i dial it in at or is it the cutting amps generated? My cutting amps are 3-4 amps more than set, makes a big difference with small cuts.

This begs the question on how you KNOW what the actual cutting amps are.

However, one explanation of why your actual cutting amps are MORE than the amps set on your PC is that the Work Lead is the SENSE line that the PC uses to determine how much current is going into the metal. If the work lead is not clamped properly, or, worse yet, your table is GROUNDED and is shunting away some of the current, then the PC can’t properly set the cutting current. This doesn’t directly have anything to do with THC, however, COULD have something to do with the way the THC is grounded.

I dont have thc yet. The Cut60 digital amp display changes when your cutting from set amps to what they call actual cutting amps. I geuss thc will negate all that anyhow, just curious.

I misunderstood your post, sorry. THC should not affect your cutting amps at all (unless the THC isn’t working). I suppose, the reverse is true though. If your workpiece is warped or distorted, then you might see varying actual current without THC. IF is working and is holding a constant cutting height then actual current should be relatively constant.

I guess the only question would be do i set it on 40 amps for say a pc of 10ga, or do i set on 37 amps expecting it to increase amps while cutting?

Do some test cuts and see what gives the best results. It may not be either of those.

I have the cut 60/Pro setup w/THC and mine does exactly the same thing. While the torch is firing, digital readout is almost always 3amps high than setpoint.

I have been splitting the difference and setting to 1-2 amps below cutchart value and never seen any adverse effects.

No problem, I’m curious about this behavior anyway.

Have you ever checked to see if this same thing happens if you do a hand cut? I’m wondering if a piece of metal, totally isolated from the Plasma Cutting table, but just using the hand torch and work clamp gives you the same offset or if the current in that case reads correctly. This goes back to my comment regarding some of the signal being shunted away by a ground or something…

A description of this is in the manual. I have not but it sounds as though it would act the same. Im going to hit up the Primeweld guys over at the fb site and see if there is an answer or reason for this. Like i said, mostly just curious, but an amp or two makes a difference sometimes, especially with 18ga type cuts. Ill post back here with it.

The part I am most curious about is why would the amps be dynamic at all once cutting ?

These machines are constant current machines by their very nature and should really be holding the amperage steadfast. PrimeWeld likely has a reason for doing/displaying this?

I can see displaying the different between the pilot arc and the main arc amperage.

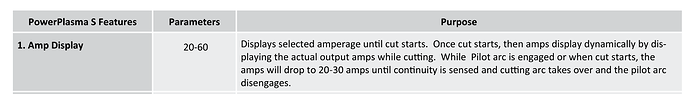

Clip from the primeweld cut60 manual.

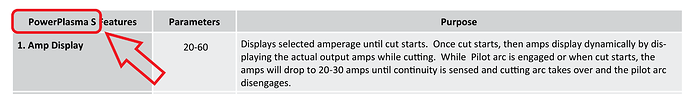

The other odd thing is why are they referring to the PrimeWeld cut60 as “PowerPlasma S” in the manual ?

Who else is the PowerPlasma S… Everlast . Wierd.

Clip from the Everlast 60s manual.

Also notice the symbol on the Everlast picture (bottom left ) that symbol means Constant Current DC

Where are you seeing the ‘Power Plasma S’ in the manual? I’m not seeing it. The thought of a knock-off would not be a new one, but the Everlast is a whole different layout etc, plus Primewelds business model is pretty good. I think they would be pretty transparent about that.