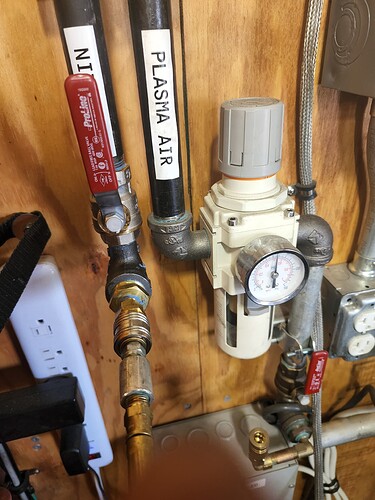

New system is almost done. I have set up multiple F5 gas cylinders to cut Stainless and Aluminum. Should be done this week for testing. I’ll keep everyone updated with results.

Not totally finish yet but 100% nitrogen work every bit as well on 11ga polished Stainless as the F5 gas.

I see no difference in 11ga aluminum verses

dry air.

Tomorrow, I will cut some coupons of each and show the difference.

The Stainless cut perfectly with just a hint of bluing about .125 in from edges. Almost no slag on back with nice smooth edge.

Tomorrow I’ll post pictures.

How did it go? Pics?

Thank you!

F5 gas bottles use special Hydrogen regulator connection. Awaiting del of new regulators.

I’ll keep everyone posted.

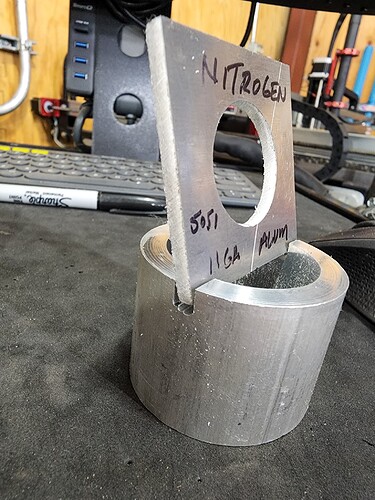

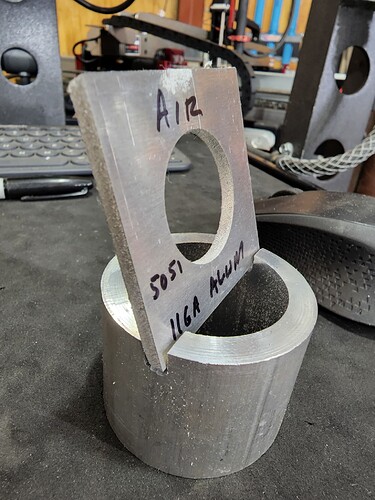

These are coupons of 5051 alum 11ga. One cut with dry air and the other cut with 100% nitrogen.

almost no difference in the two.

This is a SS 316 switch plate. 11 ga front and back with 100% nitrogen.

More to follow asap.

Hydrogen makes it hotter.

" F5 Gas Mixture (Hydrogen-Nitrogen gas mixture)

The F5 gas mixture (5% Hydrogen and 95% Nitrogen) is mainly used for cutting stainless steel. The F5 blend provides fast, oxide-free cuts, however, Hydrogen gas introduces a lot of heat into the material."

Reference Guide for Plasma Cutting Gas Selection(Hydrogen%2DNitrogen,of%20heat%20into%20the%20material.

Thats what I want it for. My gas supplier is sending over regulator for me to try. We shall see. I also cut a lot of .375 and above aluminum.

Here is F5 gas on SS 316 . Edge quality is much better. It does get hotter. I had to turn off Smart voltage due to the fact that the slag on the back was welding itself back together. I set the torch height to .06 in manual. Just a note if you try this the F5 bottle uses a hydrogen/methane regulator. A single bottle with the pressure set at 75PSI was perfect. Plasma cutter air gauge stayed at 75 the whole time.

100% nitrogen gave similar results to dry air. There is a slight bevel that could be removed by adjusting torch height.

Interesting stuff, thanks for posting. What size bottles are you using?

300 size. It should last a reasonable amount of time.

I’ll cut some 3/8 T6 tomorrow and see how it works on thick aluminum. Dry air or nitrogen worked well on thin aluminum this morning.

The F5 made no difference on small gauge aluminum. They say it works on .375 and thicker. We shall see.

Looks like a T cylinder on the left and a K cylinder on the right.

I think you’re right Tin. Weld supply had the F5 in stock for 5 years. He was happy to send them over.

Well I’m watching this thread closely. And if your results are promising I’ll be purchasing some tanks of F5. I already have a couple tanks of nitrogen but they need to stay in the van for HVAC so I may have to buy a big nitrogen too.

Dang! And here I’m trying to buy 750ml of C2H5OH…

Just can’t get lined up with youse guys. ![]()

![]()

Tom, just need to draw up the files and make you a C2H50H manufacturing machine…

F5 gas has no positive effect on thick aluminum. Tried it today and failed miserably.

Had perfect cuts with dry air, but with F5 it changes cut speed and set up. So F5 is only beneficial if you are cutting stainless steel.

I do a lot of polished SS. With that being said

I’m keeping the setup for just that purpose.

I was looking at the pics and don’t see a big difference on SS. I do get easily confused ![]()

How much better is F5 than nitrogen. Have a side by side pic of the two?

Look at the last pic in post #6,

https://forum.langmuirsystems.com/uploads/db6772/original/3X/6/0/6065ffc776cdfd4fb699780318515fa48a0cb1c6.jpeg

it is side by side comparison of the edge.

Oh I thought that was F5 to air.

Oops, my bad. I missed your request F5 vs Nitrogen. Sorry.