Is there a way I can resume from here? I clicked on generate program after getting a no voltage error and now it won’t continue from the same spot. It goes to the bottom where it hasn’t been cut and it just stops the program

If FireControl has not lost the image of your part on the visualizer and you have not moved the torch and the settings are all still intact then “Yes.”

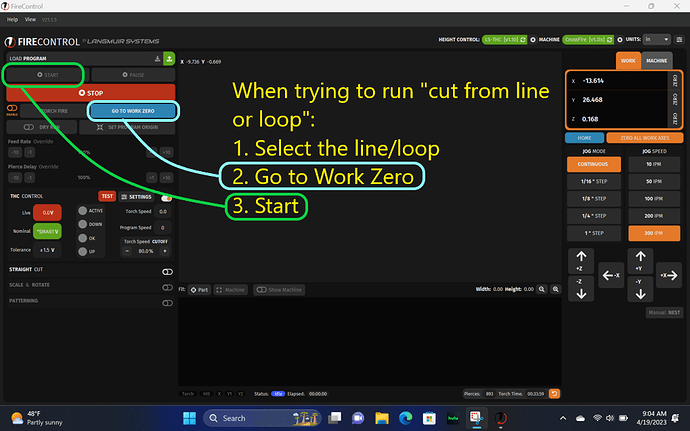

Click on the line or loop on the visualizer that you want to start the cut. FireControl will then ask if you want it to generate the program from that point. You say “Yes”.

Then send the torch to “Work Zero.” Now press “Start.”

This link goes to a longer description of what is happening and “how to do it”. It is with a 3 year older FireControl interface so some of the wording is different. I don’t think this description states putting the torch back to “Work Zero” or the starting position, but I have found that it seems to set things up better for FireControl to go thru the whole IHS and turn-torch-on scenario before it starts to cut. (But it could just be my superstition).

It;s not going to start from that spot. That straight line is all one line of code, so it will have to start at the beginning of that line and go through the part that has already been cut. Most times it will work and cut the already cut section. Sometimes you will have to put a thin piece of sacrificial metal over the area to give it something to cut.

There is a work-around, depending on a few things.

1- Do you know where the torch lost it’s cut? ( X / Y location.)

2 - Has to piece (base metal) moved?

If you know the location where the cut stopped, and the metal hasn’t moved, it’s easy enough to modify the “Cut from here” code to get your results.

(This assumes you haven’t changed home or moved your plate.)

1st - select the line of code that was running when the cut failed. If a long cut, make sure the beginning is selected. Use Start from line to generate new code.

2nd - Look at the code generated. Does is start near your cut problem. If not, go back and select another line that gets clos we.

3rd - If everything looks good, make sure (move) the torch is over the area the cut failed. Note the X and Y values from the DRO.

4th - save the generated file. I’ll try to get pics, but its the 2nd icon next to your file.

5th - Editing. Open the file you saved in a text editor (Notepad). The inital torch location sould be listed as a G0 X… Y… command near the top of the code. Change this to the X / Y location from step 3. (Where the cut stopped / failed.)

6th - save and load into FireControl.

What should occur, given everything is correct, is FireControl should move to the area where the cut failed ( the X / Y you entered), pierce, and continue the cut. This bypasses the previous cut areas if a long curwas occurring when the fail happened.

That is really detailed Terrance. I had to bookmark that. I might need that sometime. ![]()