I see a lot of ready to cut projects for firecontrol ,but hardly any for mach 3 . some that are for mach 3 are way more than 500 lines and my machine will only goto 500 lines. If anyone would be kind enough to share more ready to cut for mach 3 , in fireshare it would be greatly appreciated .

500 lines of G-Code will generally only get you extremely basic cuts - primarily simple shapes. That’s okay for simple brackets and things like that. You’ll need the full license to Mach in order to cut anything with a lot of curves and details. Most any art sign will need it. You’ll see that those contain thousands or even tens of thousands of lines of G-Code.

What have you done with your machine so far?

Ready to cut files make no sense. They don’t take into account your specific plasma cutter, amps, IPM for metal thickness let alone specific ITH or THC. Too many variables to each individual owner’s setup that has no relevance to another unless the other person has the identical setup entirely.

These tables are not plug and play for that very reason.

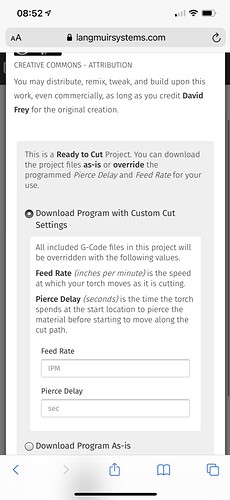

The newest ready to cut files allow you to plug in your IPM and pierce delay. It’s a great idea by Langmuir, but I’m not willing to put my designs up there for free.

Valid comment.

The OP is referencing Mach3 so ready-to-cut files are irrelevant in that respect, correct? Can’t possibly see a post processed tap file from one person will work for another person in Mach3 unless they have identical setups.

As long as it was post processed for Mach it can be cut ready, just add your own settings on download. Here is one cut ready for Mach with the settings input screen. OP just needs to pay for the full version of Mach 3.

say whaaaaat?

you mean we are not doing this for free?

why did I get into this and spend money if not doing it for free…

I am so confused now

500 lines is enough to prove the machine turns on and cuts. Maybe make super simple stuff with mostly straight lines, or something. Complex curves eat up line count quick. Some fonts can take more than 500 lines of code for just a few letters. You really gotta either license Mach3, or get an upgrade to Fire Control. 500 lines is an unacceptable limit for functionality (which is why they set the limit that low for the free version).

an upgrade to firecontrol will not increase the line capacity…did you mean Sheetcam…Sheetcam is a lot cheaper than a sub to con-fusion360…

AND…

Sheetcam’s designer is a member here…

if you wanna test your machine with cutting something, the F bomb bottle opener is under 500 lines. it’ll at least let you test the torch and your settings and refine them if need be for a particular metal thickness.

Thanks to everyone for all the input . I got mach 3 when bought my table and was still using demo version . So got that thanks . I would like the f Bomb bottle opener ,does anyone have a cut ready they could put up so i could try cutting that . thanks so much

greatly appreciated to all.

Pretty sure he was complaining about not being able to cut a program that’s over 500 lines (due to the Mach 3 demo limit), not that he was unable to generate a program over 500 lines. He’s downloading ready-to-cut G-code files, so he doesn’t really need fusion or sheetcam. But maybe I am misunderstanding something.

I am cutting ready to cuts just till I get the hang of fusion 360. Plugging at it all the time

If you’re running the trial version of Mach3, then the solution is probably to buy a license. If you already have a paid license for Mach3, then the solution is probably to contact Mach3 people about why you still have a 500 line limitation with a paid license.

I expect you will run into the same limitation, even if you are creating your own G-code with Fusion360.

Also, it might be worth investing in SheetCam (it’s really not that much), and then you can make your own g-code from any vector file without mastering fusion - you can download line-art, or draw stuff in any vector art program, and turn it into a cut file.

Ready-to-cut files are kind of a kludge - chances of them working perfectly very often are slim to none, especially on more complex patterns, due to variations in materials, plasma cutter brand / model, etc. Even a new vs ‘well loved’ high-end plasma cutter of the same model, might need slightly different settings for the best cut quality. The quality of your air supply even affects your settings (for example, I haven’t invested in a proper conditioning system for my air supply yet, so I have to adjust my settings as the humidity and temperature change to get optimal cut quality wen I need perfect parts).

If you are doing mostly art, not engineering parts, I really think Inkscape or Corel + SheetCam is a better solution than Fusion, anyway. Inkscape is truly free (frefrefree), and SheetCam is a one time purchase (as I understand it), not an annual subscription. The ‘free’ aspect of Fusion is tenuous, at best (they could just stop renewing the free hobby licenses any day - they’ve already tightened the rules quite a bit), so I really wouldn’t go that way if you aren’t doing engineering parts. It’s a lot of extra complexity and learning curve, for features you’ll probably never use. Remember the ‘right tool for the job’ thing… I’m seriously contemplating buying SheetCam to use with Inkscape, for the occasional art projects I will inevitably do with my CrossFire, because I think it might be a better setup than Fusion for art. Fusion is the BFH, but that’s not always the best tool. In fact, I’ll probably buy SheetCam sooner rather than later, for just that reason.