How many cuts or pierces would you say you guys are getting out of your tips?

Man that’s really hard to say. Amperage, air quality, speed, all play a part. I will say this though. I had crappy air and cut (4) 3/16 aluminum pieces that were about 4” x 8” with some font, and (2) 1/4” aluminum pieces the same size and material, and a few 1/8” steel pieces, then I had to change my tips. Now with good dry air I have cut (2) 24” x 24” pieces of 1/8” aluminum, some 1/16 stainless, 1/8” steel, 3/16 stell and still have a good tip. I have also adjusted my speeds as to slow of speed can cause pre mature failure to the tips as well

That’s so true ![]() The lifespan tends to be in hours of arc-on time (the actual time you’re cutting). So it all depends on use. But they’re cheap and readily available. There’s a reason they’re usually sold in packs of 10 or 20 or more (and called consumables).

The lifespan tends to be in hours of arc-on time (the actual time you’re cutting). So it all depends on use. But they’re cheap and readily available. There’s a reason they’re usually sold in packs of 10 or 20 or more (and called consumables).

Swirl rings are much longer lasting so no reason to have more than one extra on hand.

Any Trafimet 45 torch compatible nozzle & tip fits the Razorweld cutters. Hypertherm has special nozzles & tips (& they call them something else ![]() ).

).

Did you ever figure out why your torch would randomly go out? I am having the same issue.

I believe I have. One issue was water in my air line. So I made my diy air dryer setup and got rid of the moisture. But still noticed it would do it, especially on a long cut. So after some more research, I found out if your travel speed is to slow/amperage to high that the metal will melt to fast and cause the arc to go out. So after doing some amperage and speed adjustment it seems to eliminate the issue. I ran a piece that had a total cut of about 50” and the arc never went out. I think this was the biggest issue.

Where did you order the 1.0 tips from for the Razorweld cut 45?

Thanks!

I got them from Amazon - 10 for $18. They are drag tips though so you can either use them with the standard shim and they’ll be a hair too high, make your own shim that accounts for the raised nubs on the tip, or run the tip on a belt sander to sand down the nubs flush.

Gamble has good prices on tips as well - similar to Amazon for generics and about double for the best Italian made Trafimet ones.

One to add… Razorweld 45, 45 amps, .9 Harbor Freight Tip, .25 304 Stainless, 15 ipm, clean cut, .06 height

All set. Sheet is updated.

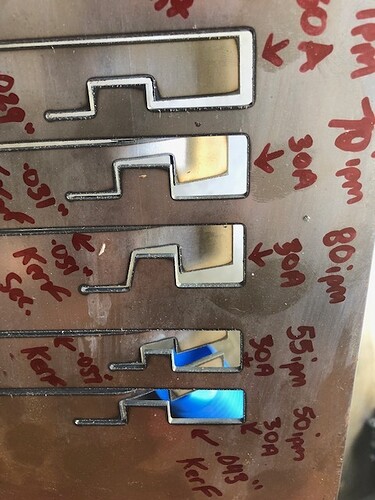

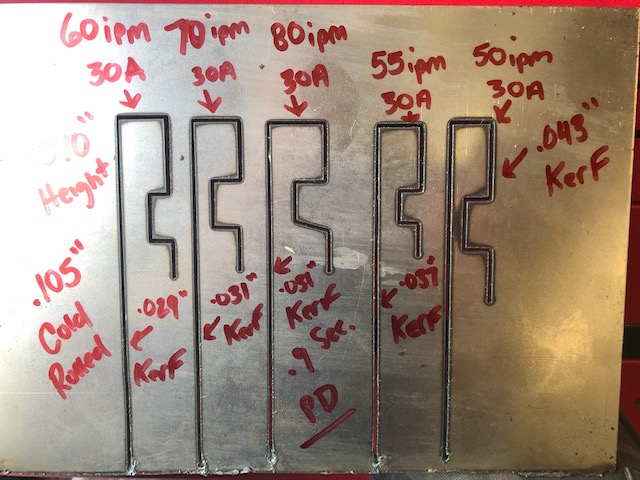

.105” cold Rolled

.070” torch height

.9 pierce delay

Water table

.8mm nozzle

30Amps

Every setting yielded great cuts.

50 ipm only had a piece of dross on the back that removed with a finger nail.

Only real diff. Was the kerf width and heat effected area on front.

I’d say 70 ipm would maybe be the winner ?

All cuts were nearly bevel from. None had any dross on the front.

If your PICKY! 70ipm test run prob. Be the best setting … it yielded a .031” Kerf at that speed and Amperage and nearly perfect cut.

All would be acceptable for my stuff😉

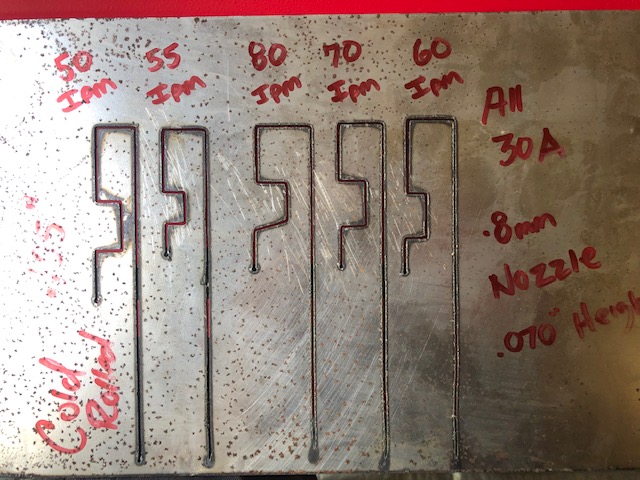

Cut a project out today

From

.105” cold rolled steel

.074” torch height

.8mm nozzle

70 ipm

30 Amps

Water table

.8 pierce delay

Near perfect cut with no dross.