I have had my table for a couple of years but only cut a few things with it, recently got it back out to tackle a project and I am having some angle to the kerf, cutting 3/16 mild steel. I know a little is expected but I seem to have an excessive amount, enough that fitting my parts together requires some grinding.

The consumables are not very old, I just re-leveled the arm and table. I am running it on 90 psi, max amp, 30in/min. I don’t have a dryer just the inline on the razorweld. Any tips to try to straighten the cuts, or is the results I have with the machine to be expected? Thanks in advance.

Could still be consumeables. Try fresh ones to rule that out. I’ve had bevel start showing up suddenly and thought the same thing. Then I realized I had more time on the consumeables than I thought.

Ok thanks. I haven’t had to buy the consumables yet, which ones have you had good luck with?

I’m not sure, I don’t use the razor weld. Someone may chime in. @mechanic416 sells consumeables.

Just don’t buy the super cheap ones off Amazon or eBay, you will chase problems all day long.

@brownfox So I ended up buying the tips .8 tips from @mechanic416 and they did not help, still a bad bevel, I ended up grabbing the .9 tips from harbor freight to to give them a shot and they cut the 3/16 nice and straight, so I was happy about that since they are cheaper and local to pick up. My main issue now is that it seems like only get about 15-20 minutes out of a new tip before it starts to blow out a bit and give beveled cuts again, with .8 and .9 running 25-30 amps on the razorweld 30. Does this seem like a very short lifespan? I do have two small inline filters.

Post pics of your worn consumables and we may be able to tell.

How big is your compressor, what kind of filters?

It could be poor air ruining those, or wrong settings for cut height, or not the right parts for your specific torch. Kind of hard to say without seeing everything.

I am a little confused here. You say you have the Razorweld 30 cutting 3/16" running at 90psi, 30 amps and 30ipm. 3/16" should be run at 40 amps, 60psi and 60ipm. So your on the border line of what the plasma cutter should be cutting. Also 90psi is way over what it should be. I also assume you are using the hand torch and clamping it by the retaining cup (not a good way to mount it) so how are you getting it square to the work piece? The cut in the picture looks good so it was cutting fine.

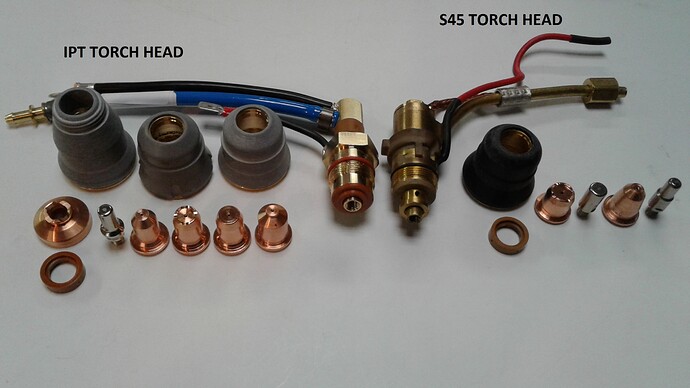

Now the Razorweld 30 uses S45 style consumables. Harbor Freight does not sell S45 consumables so your trying to use IPT consumables that are not made for the Razorweld 30 and are over rated for the plasma cutter.

So all the mixing of consumables will not help the bevel. You need to get all the same matching consumables, electrode, swirl ring, cutting tip and retaining cup. Then mount the torch properly so you can square it to the work piece. Make sure you have clean, dry air. The rest is just getting the setting right.

I hate typing

Ok I will turn the PSI back down I think I turned it up trying different things to get it to get a straight cut through the 3/16. I am running the 3/16 at 15ipp at 30 amps. I toyed with getting a bigger plasma but I only had just a few cuts I needed to make with that thickness so I wanted to try to get by. Normally I don’t cut more than 1/8.

I am a beginner and I don’t know all the ins and outs, just that I went through 3 tips trying to get the 3/16 to cut and I switched to the .9 from HF (the rest of the consumables was from my ebay order) and it cut it nice the first time (attached photo).

My main issue right now is I am eating through consumables, I just did a simple job, a 10 minute cut on 1/8 running 25 amps at 25ipm (yea it was still at the 90psi). It started the cut nice but by about half way it starts getting a bit rougher with a bevel. I took a picture of my .8 tip I used to cut it which was brand new 10 minutes ago.

Do you think the high PSI would be doing this to my consumables?

To much air pressure, moisture in the air and wrong consumables. Why are you using Tecmo style consumables on a Trafimet S45 style torch?

Here are the consumables I purchased.

The best I could determine I my razorweld has the IPT40 torch.

Which consumables should I be purchasing?

Here is what I have for filters running into the cutter.

No your plasma cutter has a S45 copy torch. The consumables you bought is for the older Razorweld 45 with the IPT40 torch. Also you need a better system for trapping moisture in the air. Those will only trap water droplets, they do not remove moisture in the air.

Picture of the two torch’s and consumables. Also Note: The swirl rings look the same but they are different.