@jwilhelm a 1/2W 100kohm SMT resistor will also work. I imagine this will be much harder for folks to install that don’t have proficient soldering experience.

Thanks. They’re actually easier to install than trying to butcher a through hole resistor onto a SMT pad. Just blob some solder on one pad, hold the resistor in place with some tweezers and reheat the solder. Once it’s in place solder the other end.

Thanks for letting those of us with a Razorcut45 plasma know about the service bulletin. I’ve been seeing the misfires with mine so I’ll be making the repair or contacting Razorweld.

I have to agree with jwilhelm I think their fix with through-holes is going to be problematic. I will certainly be using a surface mount resistor if I make the repair.

I have this issue and notice it is more frequent with new consumables installed. I personally think it is also related to not having a long enough pause time between cuts, especially for thicker material running at higher amps. I consistently have a misfire between starts and stops when I am cutting thicker metal. I am going to attempt the mod but it would also be nice to be able to adjust the cooldown time between each torch stop/start cycle to allow the tip to cool more in the post processor. If I manually pause the program between cuts and allow the tip to cool, the arc fires consistently with no issues. Using Fusion 360/Crossfire Pro with THC, Firecontrol 20.4 and the latest firmware updates

I will have to say that using this setup with no hiccups is amazing. I was able to cut four pieces without a loss of arc error. I set the pierce delay to one second and it cuts like butter.

Update: I performed the mod and it was well worth the time and effort. Previously I had an arc lost and/or torch misfire on each and every cut project. After the mod I ran several projects without a single error. This is the first time I’ve been able to do this. I’m quite pleased with the repair but I would caution prospective buyers to stay away from the Razorcut until Razorweld puts out some assurance that this design flaw has been fixed. I’ve spent hundreds on consumables and metal stock because of all the arc lost errors and in hindsight these were likely all due to this issue.

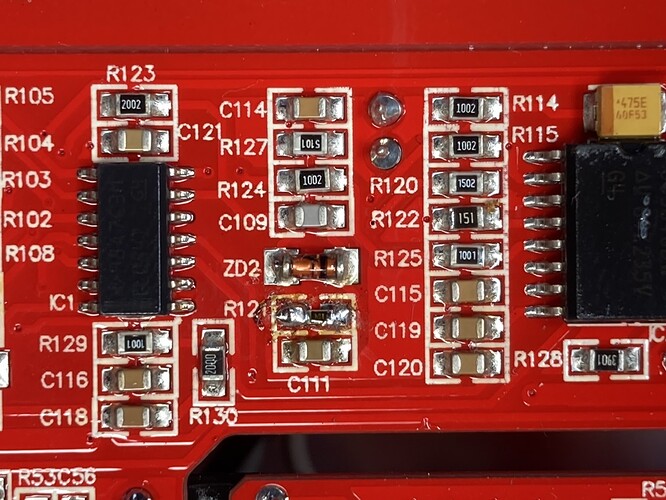

I was able to make the modification and some cuts today with dramatically improved results as well. Around 800 cuts with 4 false starts. Pictured is the fix using SMD instead of a through-hole resistor. 104 or 1003 code resistor number if you want to pluck it off of some old electronics.

As happy as I am to have things working better, I’m still thinking about a future where I am using a Hypertherm or something with a good reputation. Unfortunately I don’t think our Razorcuts are going to do well in the used market. Would anyone buy one of these used if they thought a prior owner might have been in there modifying the pcb components?

So would this also be the cause for the torch to stay on when it should turn off? I have not been able to cut a decent part yet in the 3 months I have been trying. I am thinking that this was a waste. I have a pattern with multiple holes in it. It will cut 3 to 4 holes and then when it travels to the next hole, torch stays on and cuts a line to the next hole. Bad part, it isn’t always the same spot. Tried part again and it was the second hole or 6th hole. What could be the problem…

Thanks

Do you have your torch set to 2T? If it’s on 4T it will often not turn off like you report.

Well I dry fired my RazorWeld CUT 45 40 times with no misfires. Guess I do not need to do the mod.

hi guys, i test fired my machine as i had missed a few cuts previously and it dry fired and was cutting without issue. but now that ive replace my consumables its missing again, is this an indicator that the mod should be performed? consumables were authentic and nothing else had changed. thanks

Yes. If new consumables are causing the issue to be worse that is an indication that you should perform the repair (or you can ship to RW and have them repair. They will give you free consumables to comp the shipping cost!).

thank yuou

Make sure your torch retainer cap is not too tight. It can cause sporatic misfire as well.

Thank you, to I’ll keep an eye on it!

This is not true and the retaining cup should never be left loose. There should not be any movement/free play between the cutting tip and the swirl ring or the retaining cup and the retaining cup should always be snug.

The swirl ring seals against the torch body, the cutting tip/nozzle seals against the swirl ring and the retaining cup.

The plunger in the torch head and electrode is the only thing that moves when air is supplied to the torch when you pull the trigger. The electrode makes contact to the cutting tip/ nozzle. When air it supplied the electrode moves back and causes a spark between the electrode and the cutting tip/nozzle that fires the torch.

Therefore if the plunger, electrode or swirl ring is dirty, sticking or swelled from heat it will cause misfires.

Thank you for clarifying that. I had been told otherwise, but that makes good sense. ![]()

FWIW, The consumables Razorweld sent me seem to work a lot better than the ones I got from plasmsdyn on ebay…

It’s mildly funny. I haven’t been on the forums in a few months (normal job has me working so much I haven’t had much time to do anything at my shop) and one of the first posts I see when I do is this one… 2 days after I ordered a Hypertherm Powermax 45 because I had gotten so frustrated with the false starts and pile of scrap metal caused by my Razorweld. When it’s running well it runs great but that is so woefully inconsistent I just couldn’t stand it anymore.

Oh well, I guess it’s relegated to general shop use now.

Okay having troubles … Air fire the torch, and I get a fire… if I try to fire again while the air post flow is happening it will not fire … if I wait for the post flow to shut off it will immediately fire again… should the torch be able to refire during the post flow??

Set to 2T

And not set to gas check