I might be talking apples and oranges but this is what @mechanic416 says of the different tip sizes with PrimeWeld Cut 60:

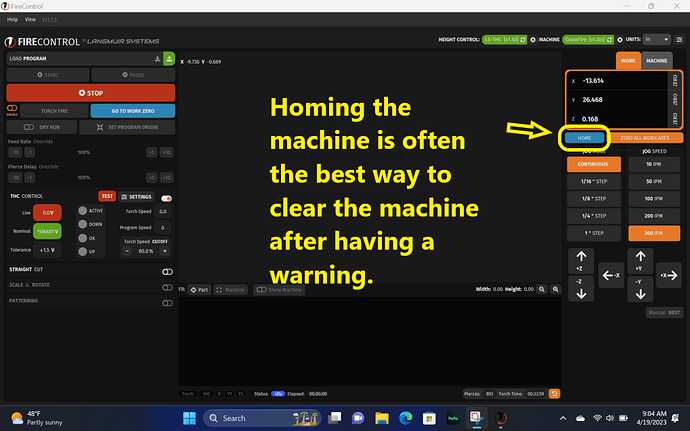

As for limit switches, definitely turn off the soft limits for them right now. To stay within the cutting boundary, if they are set up correctly, you might need to “home” the machine first.

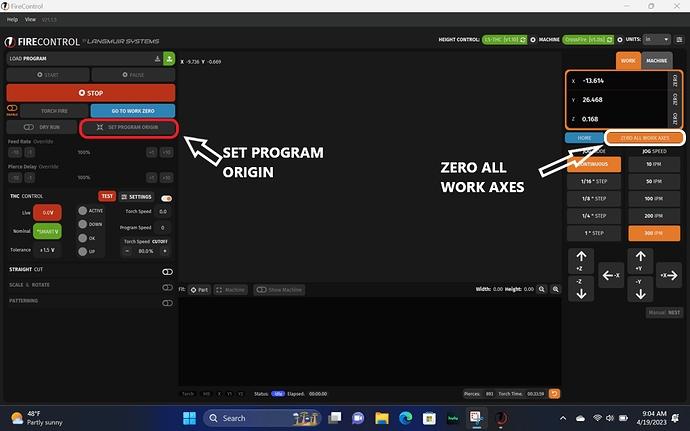

Then move the torch to the area that will signify your starting corner. Zero all axes at that point. Without moving the torch, click on Program origin and pick the green box that best represents where the torch is currently located (as per your expectation of where your design will be cut)

Aluminum is very messy stuff but your bevel seems to indicate your torch is too close to the metal or the nozzle is worn out. What you are describing is that the material is being undercut on the bottom-side of the plate. Is that right?

Is this bevel consistent on all sides?

Sharing images: