I bought the PTM-60 machine torch from Primeweld and wanted to see if I could find fine cut consumables for it. Does anyone know what I would need to buy? Any help would be appreciated.

What is the difference between shielded and unshielded? Are the shielded consumables fine cut?

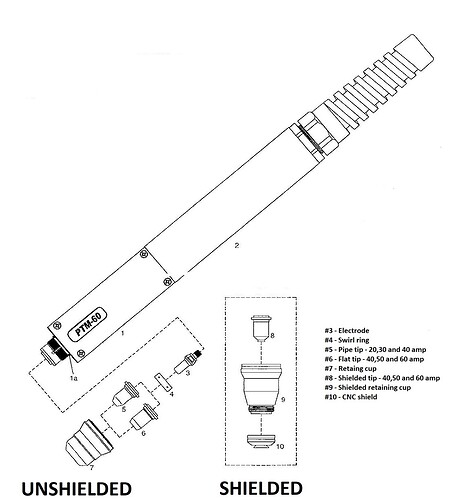

Unshielded means the cutting tip is not covered. As you can see unshielded tips come in orifice hole sizes from 0.6mm/.025" 20 amp to 1.1mm/.044" 60 amp.

Shield means the cutting tip is shielded with a CNC shield and come in 40,50 and 60 amp and work best on thicker metals. Say from 1/8" and thicker.

So thinner metal you use lower amps and smaller size cutting tips for more detailed cutting.

This is what I have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. NOTE: Orifice hole size 1mm = .03937"

20 amp tip - 0.6mm/.025" - 15 to 20 amps - 50 to 55 psi

30 amp tip - 0.8mm/.030" - 21 to 30 amps - 55 to 60 psi

40 amp tip - 0.9mm/.035" - 31 to 40 amps - 65 to 70 psi

50 amp tip - 1.0mm/.040" - 41 to 50 amps - 65 to 75 psi

60 amp tip - 1.1mm/.044" - 51 to 60 amps - 65 to 75 psi

70 amp tip - 1.2mm/.047" - 61 to 70 amps - 75 to 80 psi

80 amp tip - 1.3mm/.051" - 71 to 80 amps - 75 to 80 psi

So to get a finer cut on 14-16ga steel I should stick to the unshielded and get a smaller 30 amp (.8mm) tip? That will give me a finer cut?

Yes that is correct.

Thank You for the information! I will check out your site!

If you decide you want to get some consumables just send me a email.

Is the Kerf width the opening of the tip? say 30 amp tip, the kirf would be 0.8mm/.030in?

.030" is the orifice hole size of the 30 amp cutting tip. The kerf width will be a little wider depending on cut speed.

something to learn…kerf is something you will have to actually measure once you get your cutting refined and enter that into your cutting profiles…meaninhg you may find that a 30amp tip does a kerf of .0.39 and not 0.30 due to the fact you find you have higher air pressure…so you would enter 0.039 in kerf in your cutting profile for tht tip and amp size…

@mechanic416 , I am going to be cutting some 5/16 with a lot of pierces. I had a scrap piece of 3/8 I used to get pretty close on my settings. Im using a 50amp tip on the ptm 60 and the everlast 52i. Currently with a standard tip I am cutting at 48 amps, 74psi and 26ipm. My kerf is .054. Does using shielded consumables at those settings cause a change in kerf width? the smallest holes I have are .44. Would you recommend shielded over non shielded? Thanks.

I have used both and they seem to work well. It all depends on how you set your unit up. I like shielded consumables for thicker metal but it does take a little more to set them up. As far as kerf it should be the same.

sent you a pm.

What is your website or store name. I have the same ptm60 and was looking for an assortment as most of my work will need 0.65 thru maybe 1.0. Probably never need a 1.1.

Welcome to the forum.

George, will you send me 10 - 60-amp tips for my PTM 80 torch, please? Paypal invoice me, please.

Thanks, John

@mechanic416 a lot of useful information above, thanks. Can I use cut60 and IPT60 consumables with my PTM-60?

Do the pointed tip consumable give finer cutting capacity?

Welcome aboard.

Yes the consumables are the same, other then shielded consumables. Then the cutting tip, retaining cup and shield. For hand cutting you would use a drag shield and for table cutting you would use a CNC shield.

No its just the way they are made. A 0.9mm/40 amp pipe/pointed tip, a 40 amp flat tip and a 40 amp shielded tip will all cut the same. With the same kerf just used for different applications.

Thank you @mechanic416