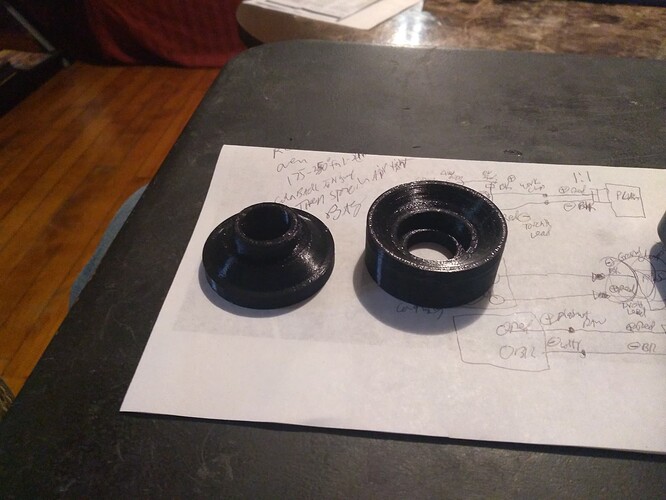

Printed that Mod 2, drain dimple die now to see if it works. I designed from the two PDF files that “dbrub2” posted in Jan 2021 (modeled in Rhino since that is what I use). After reading a few other threads on printed dyes. I will have to get some backing fender washers or plates to get uniform compression. Looks like some threads are recommending not exceeding 60ft/#’s on compression.

I used PTEG, 8 wall/top/bottom and 50% infill in a triangular pattern. I further “Cheated” and put super glue on the the “First contract” edges/walls for re-enforcement. On my printer it took 10 hours to print, Plan to post up success or failure pics when it gets done.

6 Likes

Well, the 3D printed dimple die worked fine! it was a PIA a little bit getting

it centered up before tightening down. I had the 3/4” bolt (and nyloc) lying around so had to cut a piece of 3/4” pipe to act as a spacer (would have helped to use a washer between the pipe and nut, but didn’t have one. I also cut 2 small 3/16” plates from scrap and drilled two 3/4” holes in them, the plates are larger all the way around than the Max OD of the die. The 3D printed die did not pop or crack at all. Honestly was surprised since I was honking down on it with two 2’ breaker bars to compress it. I used some “Seal All” between the rubber flange and the pan hole of the dimple. The drain was/is slightly off center, but since the seal all was starting to set, I did not change it, and it holds water no leaking.

So, for those interested, I can recommend the Mod2 PDF drawing for the base of your dimple-die without reservation!

3 Likes