Has anyone converted there T45v torch head to a Duramax machine torch head? My question is, Can I expect great results by just switching the torches? I cut mostly 10g and 14g mild steel. I am looking for a smaller kerf width by utilizing the fine cut consumables. Will I see that much of a difference at all? Does anyone know the advantages of switching to a Duramax torch??? Thank you

The Duramax torch offers longer consumable life, better cut quality and finecut consumables for better details on materials thinner than 10 gauge. It is the same torch as used on the larger Hypertherm units as well. Jim Colt

Here’s some pictures of test cuts using retrofit Duramax machine torch with a Hypertherm 600. I am using fine cut consumables on 14 gauge, which technically is not supported by the book for this machine, as the manual says 45 amps are needed at 14 guage, the 600 is a 40 amp machine. I will hopefully have time to do some more tests today using regular consumables. Does cut much nicer than my original hand torch. Not quite the comparison you were looking for.

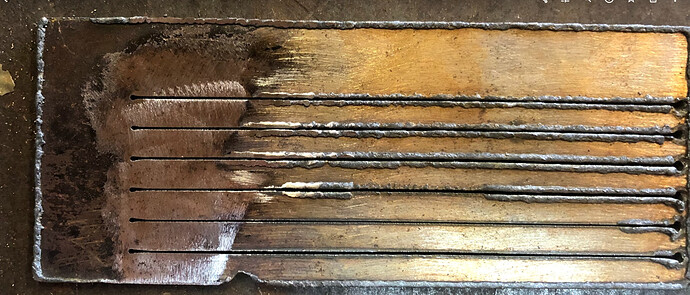

These were done with THC off, my pierce delay was too long:

backside, top is lowest speed, bottom is fastest. Hit with a flat disk on the left. The outside was cut at 140 imp.

I need to cut some shapes to see what the cross section of the kerf looks like.

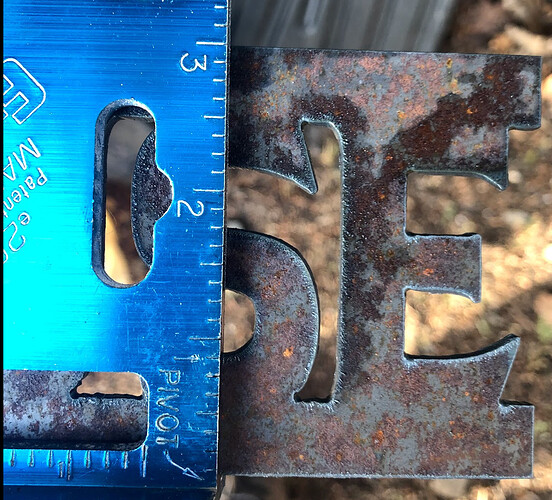

Here is an actual piece I cut at 140 imp (need to double check that) fine cut 14 gauge with THC on. There was slight dross on the back side that knocked off fairly easy. Some of the dross has been removed in this picture, some still on, this is the backside:

Front, mill scale was chemically removed on the front (Muriatic Acid) before cutting.

The Crossfire Pro is my first plasma, and these are my first cuts.

Here’s with the regular consumables, spec is 221 IPM, test lines are from 170 to 230, second from bottom is 221. Pierce delays were longer than in the manual.

backside, very little dross, second from bottom is 221 ipm

Shapes, 2", 1", 1/2" circle and square and some letters. All done at 221 IPM

backside

and here’s some more 14 gauge HR mill scale and rust at 140 ipm fine cut. Again this is on a PM 600 which technically the specs call for 45 amps and the 600 is only 40.

Top

Bottom

Thank you for all the pictures, I think I am going to make the switch. When I do ill post my results. It’ll be closer to a month though.

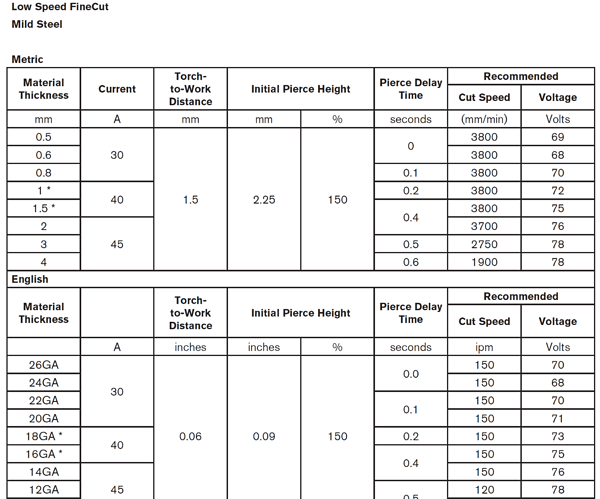

Your Duramax torch came with a manual (on a CD) that you can print. It will have cut specs for your 40 Amp Powermax600. Many do not look on the disc expecting that it is irrelevant…it has great info and all the cut specifications that will ensure you will get excellent cuts and consumable life with the 600. Jim Colt

Thanks Jim,

I have the manual. Like I posted above 14 gauge fine cut is just outside the listed specifications for 40amp, manual says 45 amps. I found 140 IMP for 14 gauge to give acceptable results, at least to me. I am interested to see how 16 gauge goes with the fine cut. The regular consumables I ran at 221 IMP (again what is given in the manual) and had good results, at least as a newbie plasma table owner.

i know this is an older thread but i was looking for info about this exact conversion and the question was asked but no one answered it instead it discusses settings and manuals for the T45V torch. I have an older Powermax45 with the handheld T45v torch. i use it on my table no problem but i always wanted to get a machine torch to keep on the table and maintain the handheld for when i needed it. I know they make a T45V machine torch but they also make the duramax line and they offer the mini which i think would be nice. Can i just get a duramax torch and plug it in? do i need to convert anything? maybe jim colt can share if he has any info. thanks.

Hypertherm s site has a little information

"Owners of the world’s most popular air plasma, the Powermax45®, can now upgrade to a Duramax® series torch, the same torch type found on Powermax65, 85, and 105 systems. In replacing the T45 torch originally sold with the Powermax45, owners can enjoy longer consumable life, better cut quality, and more torch and consumable options.

Designed for durability and reliability, Duramax torches include Spring Start™ technology in the electrode to eliminate moving parts and ensure consistent reliable starting. In all, Hypertherm offers its Duramax torch in seven different styles. Owners can choose from 15° hand, mini machine, and robotic torches in addition to the traditional hand and machine torch options with lead lengths up to 15.2 m (50’). The switch to Duramax torches also gives Powermax45 owners access to Hypertherm consumable technologies such as CopperPlus®, Max control gouging, FineCut®, HyAccess™, and FlushCut™.

“Powermax45 customers have been asking us about the ability to use Duramax torches with their system for a long time since it gives them access to so many more cutting and gouging options,” said Jonathan Murphy, a Hypertherm marketing specialist. “With tens of thousands of these in use every day, we wanted to do what we could to help owners take advantage of the newest technology.”

Hypertherm designs and manufactures industrial cutting products for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes cutting systems, in addition to CNC motion and height controls, CAM nesting software, robotic software and consumables. Hypertherm systems are trusted for performance and reliability that result in increased productivity and profitability for hundreds of thousands of businesses. The company’s reputation for cutting innovation dates back 50 years to 1968, with Hypertherm’s invention of water injection plasma cutting. The 100 percent associate owned company has more than 1,400 associates along with operations and partner representation worldwide."

Powermax45 with Duramax torch brochure

Duramax Machine Torch Cut Charts for the Powermax45

T45m and Duramax Series Machine Torches — Cap Sensor Switch Replacement