I see what you are talking about, however I wouldn’t know how to implement a 2 wire system like that, My experience is pretty novice at this point. I have only been doing this steel work/fabrication for a little over a year. Learning everyday.

You would just do a piggy back cable. The primary wire goes from the cutter to the spring clamp cable connector stud. A second cable attaches to that same “spring clamp cable connector stud” and continues to your mag clamp stud.

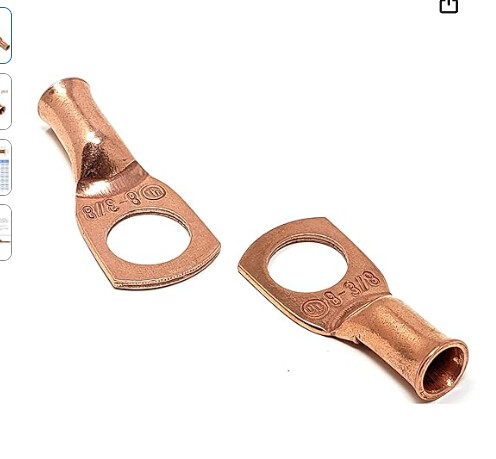

You use this sort of compression cable connectors on the ends of the cable:

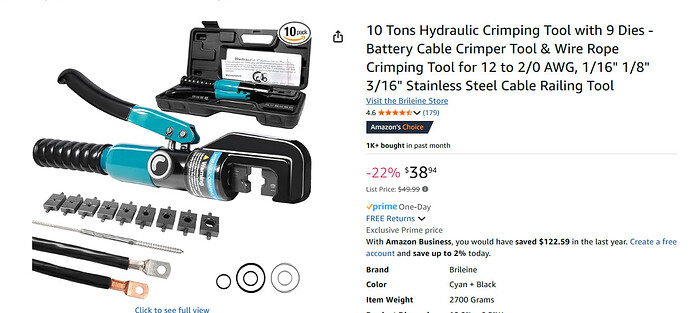

Some people use vice grips or simply a hammer to crimp onto the cable but the right way is to use a crimping device:

https://a.co/d/3dVhBEF

Great explanation, that is easy enough then.

Have a new cable and clamp coming, lets see what that brings ![]()

I took off the work ground from the machine, this is what it look like and I dont think it should look like that, as stated above I have another one coming.

Did you take it apart from inside the plasma cutter? That connection is a bayonet-type connector. Twist it. It’s hard to tell from the picture. That is the positive work cable. That bad connection may very well be your issue.

Yes, I had to take it off from the inside of the machine as I was not able to disconnect it the regular way by twisting it. The hard rubber coating on the outside would turn but it would not disconnect

Damn that thing is corroded together. I would say that was a lot of your trouble. You will have to replace the plasma cutter end also.

If you need a new part for the plasma cutter end let me know as I have some.

You could also contact Everlast and get one.

This is very interesting. I wonder if there is some arcing in the bayonet coupler. Losing the work clamp connection will definitely affect the control strategy.

I also wonder if you’ve had moisture ingress into your work clamp wires that crept down (capillary) to the connector and rusted out / fused.

You mentioned taking “raw” voltage for the “Arc Voltage Control”. Where are you sourcing it from?

You might be right about the water creeping as I used to have my cutter under my machine before I made a shelf for it. For the raw voltage I have it connected directly into the machine on the clamp and torch. Just following the instructions that Langmuir gave me

I would say it would be a good idea to go in and check all those connections and wires also.

Ok, I got a new ground clamp and changed it out. Still getting misfires. What should I check next?

I have had DMs with @ChelanJim and we agree that I do need to get a better compressor. Today I had misfires before the compressor even kicked on. Do I contact Langmuir and try to get a new THC controller.

My machine was down for the last week and I was doing troubleshooting with Everlast, End of being a frozen piston thing on the machine torch. Put the hand torch back on to start working again. During the troubleshooting I went to the electronics panel and made sure all connections were tighten. I am going to swap out computers just to see if the Window surface pro is causing a problem just thinking outside the box with the wierd magnetic keyboard.

Ok, so maybe @ChelanJim is on to something. It just might be a compressor issue. I started another cut 3 letters into the compressor kicking on I had a misfire. I waiting about 5 minutes and then started the cut again an it went for a bit and then misfired again. Jim did say I would have to put pauses into my code to let the compressor catch up. I did a couple of times where it seemed that the solenoid got stuck open(could that be a compressor issue) and I had to turn off the power cycle the machine. Once on it started cutting again. I have another compressor coming next week but still need to install another 220 outlet. I am trying to document everything I am having to do so that if anyone like me comes to visit this site they see this post. I watch a few you tube videos before I bought and they recommended this compressor. I see other post now that say don’t buy anything less than 10 CFMs. Maybe its not only the compressor I am still trying to troubleshoot this issue. Part of troubleshooting is to rule out everything you can and work your way backwards. My compressor is pushing 75 PSI to the machine constantly but apparently my lack of knowledge shows its just not about PSI.

You should wire the compressor direct to the electric panel. They should not be on a cord. The solenoid can only stick open if its bad, over pressurized or got something like dirt or rust stuck in it.

Can you do that, is that up to code? I will talk to my electrician this week about it. Thank you for the reply!

Which compressor are you running? Do you have a desiccant moisture trap, or just the 2 filters in your original post?

I’m running a husky 27 gallon 200 PSI. Pictured below. I have the NPT Air Drying System - Double Air Filters, Air Pressure Regulator Combo with also the air dryer on the back of the Plasma cutter. Not sure what the difference is with a desiccant moisture trap and the one I have.

Thank you for your reply.

None of those things is drying your air. They may catch some condensation as the air cools, but there is much more water vapor still in the air that is getting to your plasma cutter.

Add a 1 quart sized desiccant dryer and a motorguard filter for much improved consumable life. You’ll be surprised how quickly those blue beads turn pink from absorbing the moisture in the air.

That may not fix your problem, since I think you have a solenoid problem, but it may have contributed to the sticking solenoid.

Hopefully you have some small projects because under normal circumstances that compressor will be running 100% duty cycle damn near to keep up.

And because it’s always running at 100 it’s going to run hot and because it’s going to run hot it’s going to sponge up and hold on to moisture in air longer.

That compressor is not an ideal pairing for plasma cutting. Unless you’re really just doing tiny art projects once in awhile.