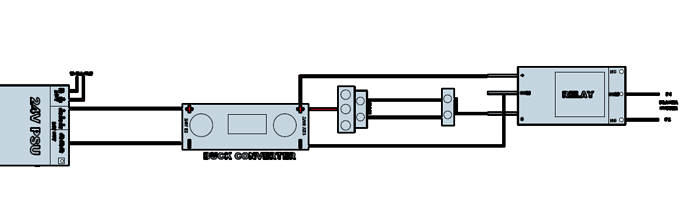

I’m not sure how a 5V power supply factors into the torch fire. You just need a contact closure, either NO-COM from a relay.

Ok, that’s what you hook up to your relay contacts.

Yeah, good solution. The fan port should be fine, you just need to know what voltage is driven from that port. It’s typically 12V so you would need a 12V relay.

It’s easy to modify the SheetCam postprocessor to change the command and add the dwell for pierce delay.

Here’s a snippet from the Mach3 Plasma postprocessor.

function OnPenDown()

if (preheat > 0.001) then

post.ModalText (" G00")

post.ModalNumber (" Z", cutHeight * scale, "0.0000")

post.Text ("\n G04 P")

post.Number (preheat,"0.###")

post.Eol()

end

post.ModalText (" G00")

post.ModalNumber (" Z", pierceHeight * scale, "0.0000")

post.Text ("\n M03\n") <=== CHANGE this to M106

if (pierceDelay > 0.001) then

post.Text (" G04 P")

post.Number (pierceDelay,"0.###")

post.Eol()

end

end

function OnPenUp()

post.Text (" M05\n") <==== CHANGE THIS TO M107

if (endDelay > 0) then

post.Text (" G04 P")

post.Number (endDelay,"0.###")

post.Eol()

end

end

There are some GRBL post processors, probably what your Duet board uses.

Custom Post processors should go in:

C:\Users\USERNAME\AppData\Roaming\SheetCam TNG\posts

Edit an existing post, rename it, and save it in this folder…

Also, re your WorkBee center support bars, IFF you are using this for ONLY Plasma, you can remove the bars without any problem. They are there if you’re doing CNC Routing and are needed to handle the front/back torque from the cutting. There is no such torque with Plasma cutting.

IF you are also using this as a CNC router, then you may need to create an Exoskeleton OUTSIDE the cutting area to provide the support needed for CNC routing. I suspect a couple of 2040 bars, laying on their side, attached to the front and back will make it stiff enough.

Sure I can help, no problem, but I may move this thread to an ‘off topic’ category…