I’m having a hell of a time with my letters for monograms . Was working perfect now it’s terrible . I’m using fusion 360 to sheet cam . Like I said it was great for a while now

So what’s the issue Alex?? Someone will most likely be able to help or lend some advice!

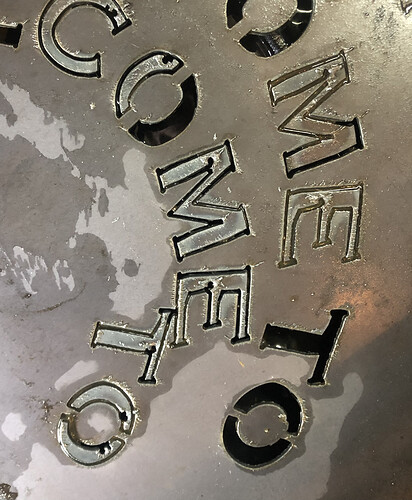

Lettering is not consistent. O’s that should be rounded are sometimes jagged. L”s taper down and don’t stay squared. I might have to take some pics . I was doing some perfect cuts about a month ago. I sent some lettering from Inkscape and that cut worked better but fusion lettering not so much .

I had a similar issue recently. Turned out to be slippage on the lead screws Y axis. Might want to check your couplings. All the sudden changes in direction on lettering magnify the issue.

I put 2 pics here . One shows how the lettering looks and the other shows who the word “to” went below “welcome” instead on the same line

wow…I think you have several problems…

are these your fist cuts…or is this a recent problem?

unless your letters are supposed to be misshapen you have loose couplers.

Your gantry could be binding…remove the drive screws and you should be able to slide the gantry around without any force…

top dross is a result of the torch to high or traveling too fast.

what metal thickness?

what torch speed?

what amps?

what pierce height?

what Pierce delay?

cut height?

Yeah Alex… I see what you mean!

Like mentioned above, the mis-shapen letters and letters out of place are most likely to be the result of a loose lead screw coupler. Take a minute and go through all your couplers and set screws on them to make sure all is good as far as that’s concerned… I’d be willing to bet this fixes that problem for you… If not, please let us know!!

Secondly, I see some letters not cut through completely and a fair amount of “top dross” around the cuts… If you haven’t already, make sure to get your work clamp directly on the material you are cutting and don’t rely on a slat or otherwise to make a good connection for you… You may need to increase amperage, or slow your feed rate as well in order to alleviate this issue…

Would love to see a picture of the entire project too… I always like to see what others are cutting…!!

Good luck and let us know if things work out for you!

Bill

These ones are passed projects . It’s gotta be mechanical. Bigger lettering seems to run smooth but the smaller stuff not so good . Im using all recommended settings and ones ive always used . Uploading: 1883F13E-A032-4BBE-B337-DC2FCBF35F5C.jpeg…

I’m sifting through your suggestions

you obviously know what you are doing…nice sign work…

that rules it down to mechanical…

I re adjusted everything, I slowed the cut right down . It cut better but there’s some discrepancies that are still irritating. I’m also thinking I’m getting a lot of moisture because of the humidity so far this summer . I have the basic filters but nothing like air dryer .

a simple solution that doubled my pierce counts…a copper pipe cooloer mounted on the wall right after the compressor…

there are a lot of pictures here of copper air coolers…

I will be installing a refrigerated cooler later…but the copper pipe did wonders…then just before the plasma…desiccant beads and then my motorguard filter…