So ive had my machine a couple of months now with anout 3 hours of free time to work with it and so far no complaints. As i get into cooler weather and more time newer projects are going to require different thicknesses and types of matetial. With that said is there any better method or maybe rule of thumb to setting a starting point for pierce time and ipm than trial and error? Seems to me thats a lot of wasted time and material although im relatively new at this and could be wrong.

What kind of plasma cutter do you have?

Everlast 52i, with i believe the 1mm nozzel or whatever comes as stock.

I think I have read a couple threads where @mechanic416 has suggested using the Primeweld cut chart to get you close when using an everlast machine.

I tagged him so he can correct me if my memory is off.

There are several members like @toolboy using everlast machines that can steer you in the right direction.

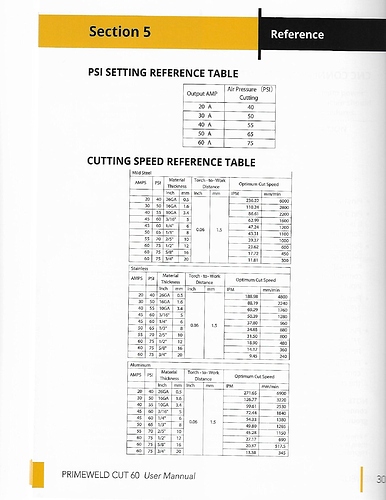

Maybe this will help.

Yes the cut chart you posted is a good starting point for the Everlast 52i.

I have a 60s with machine torch from Mechanic416 and I leave the plasma set at 50 amps and vary the cut speed and I’m happy with the results. I cut 14ga at 150ipm.

Thank you. I much appreciate the input.

@mechanic416 Ive heard a few times youre the go to guy for consumables and information. Do you by any chance take orders over the phone? Im not to crazy about online shopping.

I had to stop taking orders over the phone because of the fees and fraud.

I do take orders by email and use paypal invoicing for payment. I don’t charge fees or tax.

Thanks for asking.

George