That is a great-looking bench—high-dollar aluminum? Haha, is there a high pucker factor in cutting that backrest scene?

Probably the highest pucker factor you can get to on a langmuir plasma table.

That one panel with the crane was over an hour of cut time with 150 pierces. You had to watch and listen like a hawk because aluminum can foul that consumable so quick. I think I checked the consumable condition 15 times or more during that cut. That one panel to set up cut sand and clean up is just over 3 hours of work. Lol. This project’s coming out a lot better than I expected but I also am going to be happy when it’s done. I’ve cut a lot of quarter inch aluminum before on the XR but these panel cuts gave me an entirely new appreciation.

I know you use a Hypertherm machine, but since I switched to shielded consumables from George for my Everlast, my aluminum cutting has greatly improved. I also use nitrogen for aluminum cutting instead of air.

What would you estimate the gas cost for one hour of cutting with nitrogen gas vs. Compressed air?

Those are some pretty fancy visuals you provided with that post.

I can only imagine the anxiety with such a project. Lots of grinding discs would need to be included with my bid!![]()

Each bottle costs $30 for the 300 series size. This price is for just the gas. You’ll need two bottles and regulators. The gas lasts a considerable amount of time, assuming you already own the bottles.

9 cubic foot tank of nitrogen here which I buy often for doing refrigeration work is about $60.

So the question is

“if I have a 9 cubic foot tank of air filled to 2,500 PSI how many cubic feet would that air be at 100 PSI”.

And the answer to that is.

at 100 PSI gauge pressure, the air would expand to about 197.2 cubic feet

And when cutting I would use between 6 and 9 cubic feet a minute.

So let’s use 7.5 cubic feet. Every minute. And then add a another 4 cubic feet for every Pierce to take into account that pierced time and the post purge.

If you work through the math 1 9 cubic foot tank would not cut my panel. A 15 CF would.

I am going to try nitrogen though see how it cuts.

So in Canada I’d probably use about 60 to $90 per panel of nitrogen per panel of nitrogen.

I’m sure I would get a better rate with a large t sized cylinder but I only carry a bunch of nines because I do lots of refrigeration.

It improves the edge cut but is unnecessary for anything thinner than 3/8 aluminum. I just have it rigged up, so I use it. I have a manifold system with Nitrogen bottles and F5 bottles, depending on what I need. It will help with intricate cuts.

Beautiful work. You are a brave man clicking on “Start” with that AL laying on the table. ![]()

But please tell your partner he’s making my back hurt. He needs to raise his work area a bit and save his back from all that bending over. Ergonomic accommodations in the workplace for the win!

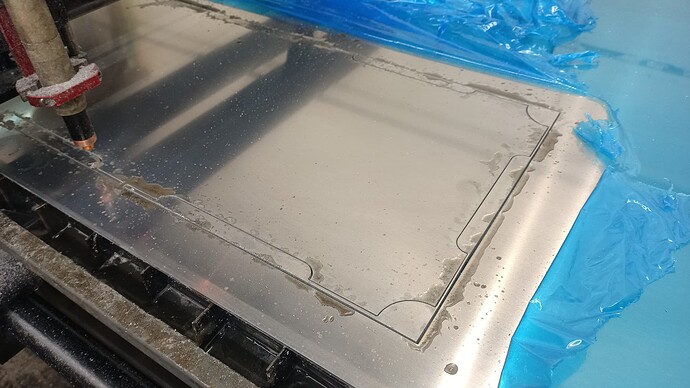

Finally cut the last panels for this bench project.

Sure slow go. The one panel with the kayak for example has just under an hour of torch on time, 140 pierces then I timed it as just about an hour and a half total time because you have to stop and wipe the sheet and check and change the consumables quite often with the quarter inch of aluminum.

Five benches all gettingdelivered for powder coating today. I’ll try to get some better pics of them together as we’re moving them. We normally powder coat in House but we don’t have an oven to fit these.

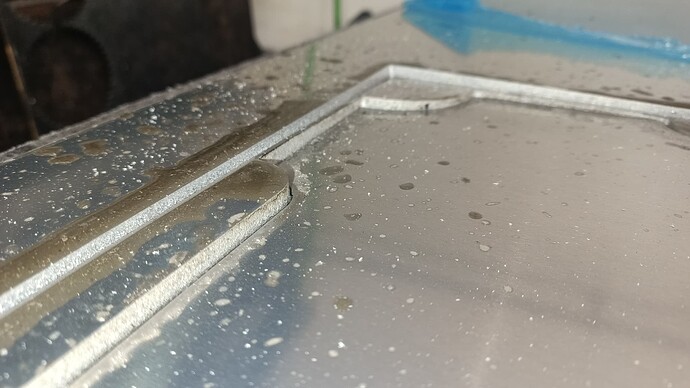

These pictures are before clean up.

You can also see in the picture why I cut a perimeter cut to relieve the tension on the sheet before cutting the internals.

I am looking forward to taking a break from quarter inch aluminum for a week or so. Cutting steel this week is going to feel like being on vacation.

I’d bet!!! Never cut 1/4 inch aluminum but the expense of a mistake has got to weigh on you.

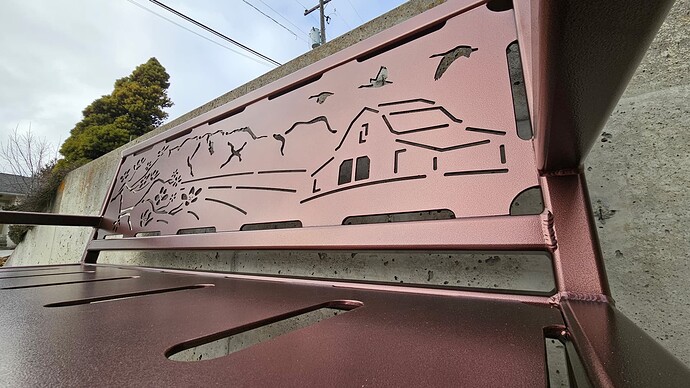

Those look really nice, TW! Your city will be proud of them!

TinMan, great job! I bet you’re glad that’s finished.

Thanks guys.

I’m proud of what my business partners and I did.

Definitely felt like we pushed our limits both in our own capabilities and in our equipment’s.

learned a few things, screwed up a few square feet of material.

These benches should last a lifetime.

I am happy with the final product.

Those BYOC (Bring Your Own Cushion) benches turned out really great.

I have heard tell that to be invigorated in life you want to do things that:

- Push the limits of your abilities

- Do something of value

- Do something unique that others appreciate

I think you and your partner scored bigly on this endeavor.

BTW: Spring must be on the way. I heard a flock of your geese next door yesterday!!!

They are definitely functional works of art. Well done!

Another couple were installed.

Pretty barren surroundings currently. I think there is some sidewalks and shrubbery planned

Those benches will provide for decades. I expect there will be postcards with them in the near future.

You and your team should be very proud.