When you need a hole for a 1/2" bolt. The bolt needs to slide easily through the hole but not be sloppy and I don’t want to have to drill or grind it larger for the bolt to fit. Is there a good rule of thumb for the size to cut the holes so they’re snug but allow the bolt to pass through? Is it like 2% larger or what do you guys do?

I don’t know the proper way but I make 3/4" hole .80 instead of .75.

Gives me a little leeway.

Alot of this is going to be determined by your edge quality and material thickness. Thicker material will have more taper and therefore need to be cut bigger to fit your required hole diameter without additional steps.

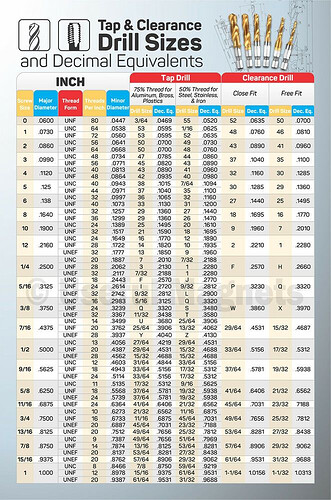

Just the old clearance drill chart used for decades by machinists world wide… You can find it in metric too!

Also you need to make sure your kerf is dialed in as well, or if it is off then you need to offset your hole diameter

For drill bits .030/.031 is nominal, so 1/4 bolt gets a .281 and 1/2 gets .530.

Like above with the kerf, taper and roundness, my thoughts where to start there and see how plasma works out.

I follow the same crude rule. .05 over the bolt diameter works for me up to 1/4" thick material.