I cut my first big sign on my Crossfire Pro for some family. It’s 44” x 33” but when i went to cut the outline it started in the middle of the top at 31” and end at 33” on the other side to finish the cut. The cuts didn’t meet up at all, in addition to that it missed rounding a corner as well. Is the anything i’m doing wrong?

wow, that is interesting. You probably be asked for job files, better post them.

It looks like you may be losing steps due to motor coupler slippage. In other words, a motor coupler may be loose, not properly gripping the lead screw or the motor shaft.

An easy way to check for motor coupler slippage is to take a sharpie marker and make three dots that are lined up to one another: one dot on each motor coupler, another dot directly next to it on each motor shaft, and another dot directly next to it on each lead screw. If the dots do not stay aligned to one another as the machine jogs, the cause of the issue is definitely related to motor coupler tightness.

Try tightening the set screws in the motor couplers until they cannot be tightened any more, and check for set screws that may be stripped.

I suspect something else is wrong(CAM) because the rest of sign is fine unless slippage just happened to occur after the letters are cut.

Do you see this discontinuity in FireControl? Please post your nc job file.

I do believe I have the REAL answer…lol…

so Watson my dear boy…

the sign is 33" x 44"…so unless the toch was PERFECTLY zeroed at the start of the 33.3" envelope then it would have hit the gusset plates

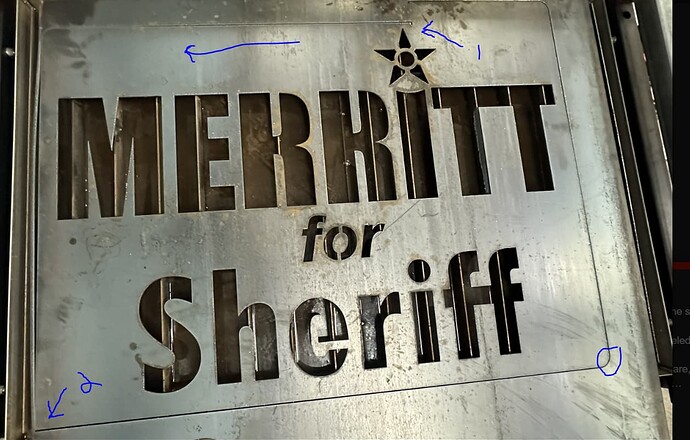

It looks like the outer perimter was cut in the counter-clockwise direction due to the start divot (1) at the top of the sign…

the plasma traveled to the left direction made the first rounded corner…then traveled down to the bottom where it jammed or ran into the gusset plate (2).

Then not throwing any error it though it did the round corner, but it is actually square, then traveled the rest of the way around the perimeter not knowing it had missed the round corner…

Elelmatary Watson…Elementary,…

I zeroed the table at the very bottom corner of the table so it should’ve had the clearance unless beind zeroed in the exact corner is the issue

I’m currently at work right now but i will post it as soon as i get to my laptop. The fire control threw no errors or codes. I also cut it last night and just got around to posting about it on my break so the used program in the fire control may not be there

I understand you “zeroed” out the torch…but the table is 33 1/4" cutting area…so if your sign was 33"…that would have left 1/8" top and bottom for clearance…and from my 4 years using the Pro table I do not think I would attempt that cut envelope…

the way to see if there is any issues with the code…cut it at 75%…see if it works…

@hitaparkedcar

Hey there! I frequently cut things that push the limits of my machine. I even modified it till I can cut better than 36 inches in the y axis. A good tip especially if you think you may have hit the limits. Always jog the perimeter to make sure no issues. I even do this on small items as well to make sure I don’t accidentally cut into a previous project.

Nice catch, squared corner.

Thanks Craig…the square corner compared to the round corners and the pierce divot clearly show the direction and what happened…

I figured the border cut with inside pierce was a CAM setup error.

I bet if he took the same pattern and cut it at 75% size it would be just about perfect…

Hey, @hitaparkedcar I went ahead and bumped you up a trust level on the forum so you can share your file.